Core Veneer Drying Machine

Core veneer drying machine has the merits of high productivity,energy efficiency,lowest drying cost and perfect drying effect.Face veneer dryer uses waste wood fired air heater without thermic oil or steam boiler. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness. Biomass veneer dryers machine is our patent,which can burn all kinds of waste wood direclty to reduce fuel cost mostly. We can design different models veneer drying line to meet users requirement.

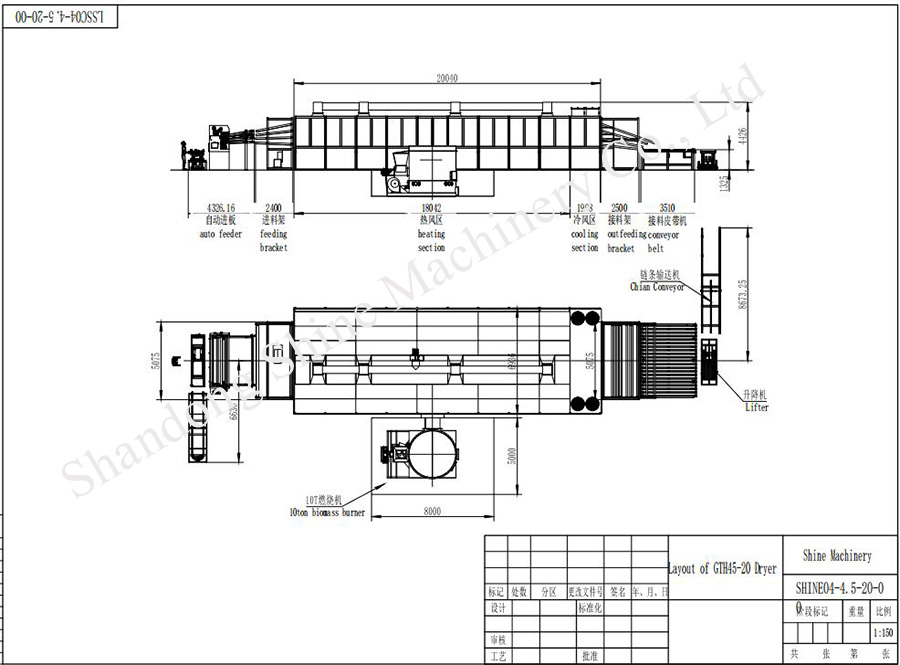

Product Description of Core Veneer Drying Machine

Shine high drying capacity core veneer drying machine is one of the most popular woodworking machines .the veneer dryer machine can be from 15cbm to 150cbm per day. Shine roller plywood veneer dryer can be designed 1 deck ,2 deck or 4 deck according to different customers' requirements.

Normally if the capacity requirement of the roller Veneer Dryer Machine is high . user will choose 2 deck or 4 deck veneer dryer.The main advantages of the 2 deck roller veneer drying machine is that it can save areas and improve working capacity.The core veneer drying machine produced by Shandong Shine Machinery Co., Ltd. is widely used in flatting drying of high-grade plywood, multi layer board and architectural core face veneer.It is equipped with environmental protection type hot air stove. its characteristics: save fuel,twice use of hot air , increase heating speed.the veneer after drying is flat,moisture content is up to national standard.

Core Veneer Drying Machine on Site in Myanmar

semi automatic veneer collection system of core veneer drying machine

The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost mostly. Compared to steam type or heat conduction oil type veneer dryer machinery, the drying cost is reduced greatly.

Product Parameters of Core Veneer Drying Machine

Model No | GTH30-20 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 16m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 2.5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(16pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(1pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 145.5KW |

Actual electricity consumption | About 100kwh per hour |

Videos of Our Customer Scene Core Veneer Drying Machine

Project Case and Customer Visiting

Customers from Malaysia visit

Our Certificate

Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation