4 Deck Veneer Dryer

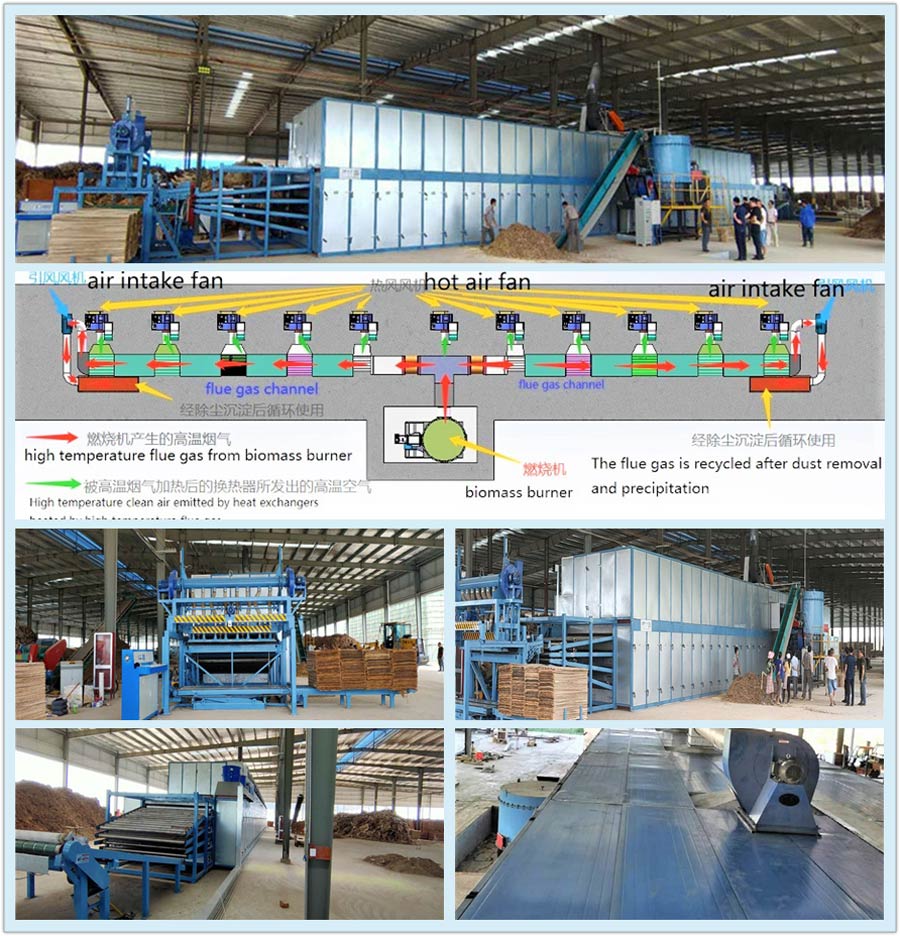

The 4 deck veneer dryer runs without thermal oil heater or steam boiler. It uses waste wood fired air heater/Biomass Burner which is our new patented product. It eliminates heat loss by directly heating air and supplying to the dryer instead of indirect heating of Oil or water. As the waste wood, waste veneers, tree barks, rind, chips, etc. are the most cost economical fuel compared to the coal, gas, steam or oil and the burning temperature is high enough to dry veneer to a right moisture content level, the shine 4 deck veneer dryer has the lowest drying cost. The temperature in the biomass burner is up to 800 degree celsius and 140-180 degree celsius in the heating section of the dryer, which is enough temperature to remove the extra moisture out of the green veneer.

Product Description

The 4 deck veneer dryer is a modern continuous veneer drying machine in plywood & veneer making process. The 4 Deck veneer roller dryer features the aesthetic appearance and can consistently produce high quality veneer with uniform moisture content. The 40m 4 deck Veneer Dryer customized working width of 4500mm.

The 4 deck veneer dryer adopts the latest technology of pressurized contact veneer drying and can dry the veneer thickness range 0.6-0.8mm. The rollers play the role of pressing and ironing the surface and back of the veneer.So the dried veneer is very flat, no end waviness and moisture content is uniform.

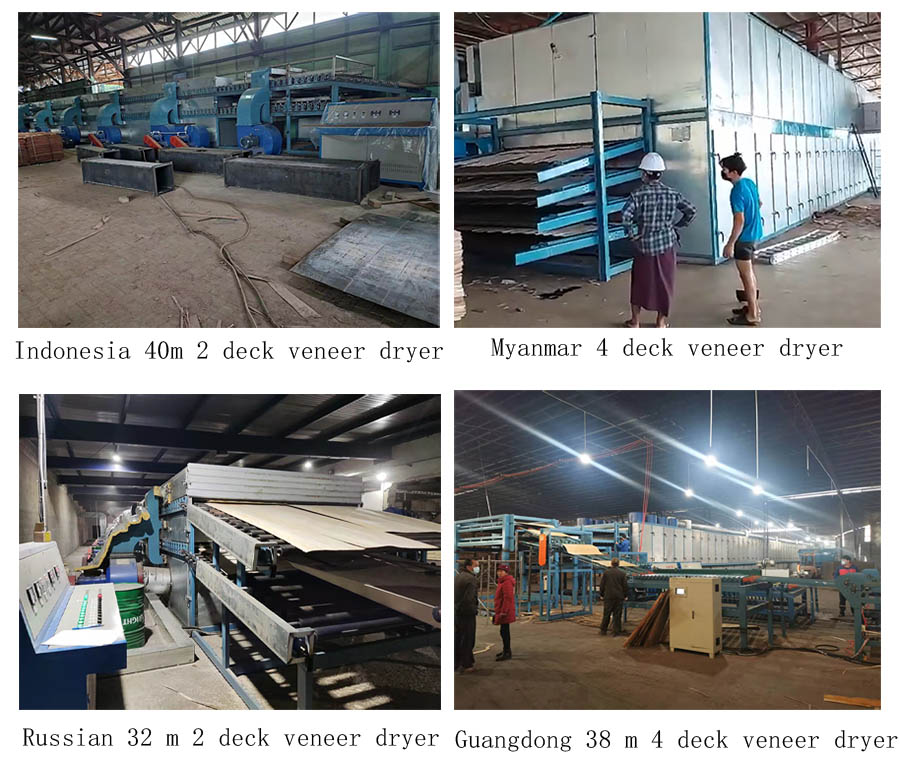

4 Deck Veneer Dryer in Myanmar Customer's Factory

4 deck veneer dryer

Shine biomass veneer dryer has the features of high veneer drying productivity,energy efficiency, lowest drying veneer cost and perfect veneer drying effect.The composite running cost is only about $12/cubic meter,which can improve customers' profit space greatly.

The working layers, working width, and heating length of the Shine veneer dryers are available to be customized as per customers' specical requirements.

Shine Machinery is the only one factory in China who can make not only veneer dryer but also the heat source of the roller dryer, namely, biomass burner.

Veneer Dryer in Malaysia Customer Factory

Unlike the steam boiler or thermal oil heater which are traditional heat source installed for the dryer, the biomass burner is the exclusive patented product that can completely burn crushed wood chips, and tree barks directly as the fuel, solving the waste accumulation problem in the veneer and plywood making factories. At the same time, the fuel cost is reduced mostly.

Professional R&D team can design different veneer dryer models according to customers' special requirements. Perfect after-sale service system can ease the mind of customer after installation as we supply 24 online services and remote operation. Regular follow up service for old customers, and sufficient spare parts supply in time.

Running Video of the 4 Deck Veneer Dryer

Technical Parameters of the 4 Deck Veneer Dryer

Model No | GTH45-40 |

Working Width | 4.5m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 8 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 11KW(18pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

15ton biomass burner | Power: 16.5KW |

Total power | 290.5KW |

Actual electricity consumption | About 200kwh per hour |

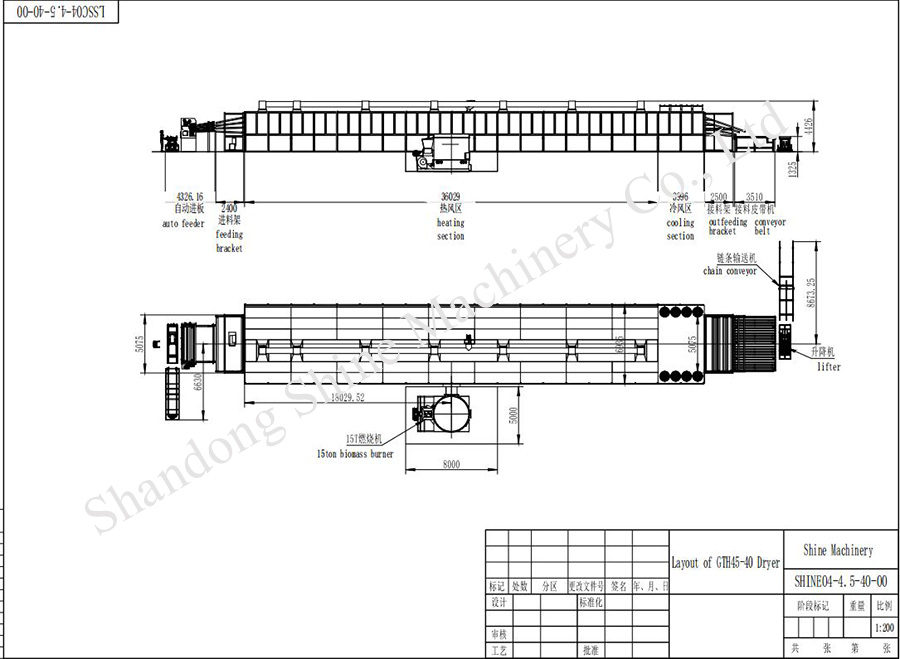

Layout Drawing of veneer dryer model GTH30-40

Certificates of Shine Veneer Dryers

Roller Dryer Worksites

Veneer Dryer Loading