40 m Wood Veneer Dryer Machine

Shandong Shine 2 deck 40 m wood veneer dryer machine adopts frequency conversion control, which can adjust the transmission speed and temperature according to different veneer thickness and moisture content to achieve the ideal drying effect. Low failure rate and reduced downtime.

Veneer thickness:0.6-8mm

Veneer water moisture:Fresh veneer to about 10%

Actual electricity consumption:About 110kwh per hour

Product Introduction of 40 m Wood veneer dryer machine

40 m wood veneer dryer machine has the merits of high-efficiency, saving-energy and good drying quality because of adopting new high technology and advanced control technology. The working width of Roller Veneer Dryer is 3 meters and can dry 0.6-8mm,the minmium can be dried to 0.

The drying capacity of 40 m wood Veneer Dryer machine can achieve 2.5m³ per hour. Veneer Dryer Machine consists of inlet,drying area, cooling area, outlet.Drying size is customerized according to the production capacity, process and space.

Veneer Dryer Machine in Zimbabwe Customer Factory

Veneer Dryer Machine in Congo Customer Factory

Biomass burner

The biomass burner,a patented product independently developed by our company, can directly use crushed wood waste as fuel to provide a heat source for the dryer, which is energy-saving and environmentally friendly,and greatly reduces the drying cost.

Biomass burner

Advantages of 40 m Wood Veneer Dryer Machine

1、The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

2. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content.Simple operation and low failure rate.

3. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil),and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

4. After drying, the veneer is smooth, with no cracks,wrinkles, or end ripples.

5. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

6. We have a professional R&D team which can design different models according to customer’s special requirement.

7. The perfect after-sale service team can supply 24 hours online service.

Veneer dryer chain, Roller running veneer, Outfeed

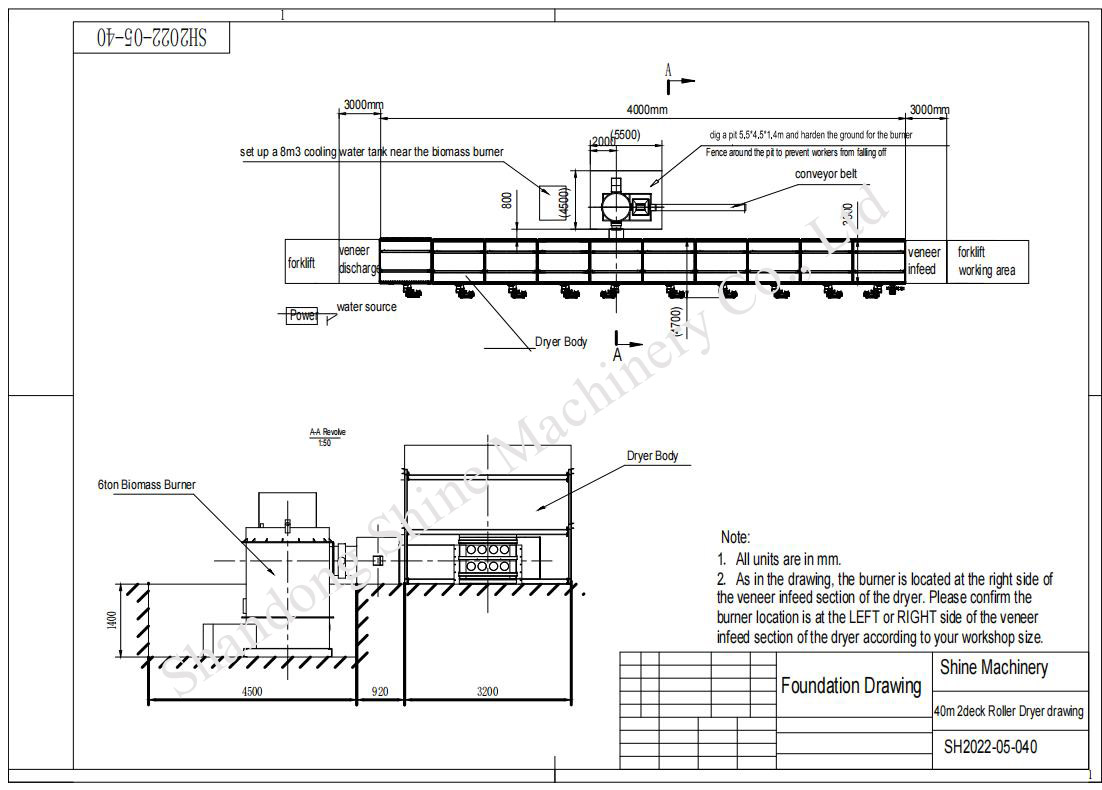

Layout Drawing of 40 m Wood Veneer Dryer Machine

Are you still worried about the poor quality of the dried veneer, choose our veneer dryer, the dried veneer is of good quality and cost-effective.

Customer Site Video

2Deck 40 m Wood Veneer Dryer Machine in Indonesia customer

Product Parameters of 40 m Wood Veneer Dryer Machine

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:11KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 11KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 163.5KW |

Actual electricity consumption | About 110kwh per hour |

Project Case

veneer dryer machine of Myanmar customer

Our Certificate

Parts of Veneer Dryer

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment

7.Provide technical exchanging

8.Door to door service is possible

Product Packaging And Transportation

Other Protuct of 40 m Wood Veneer Dryer Machine

Automatic Veneer Feeder and Automatic Veneer Collection System