Veneer Dryer

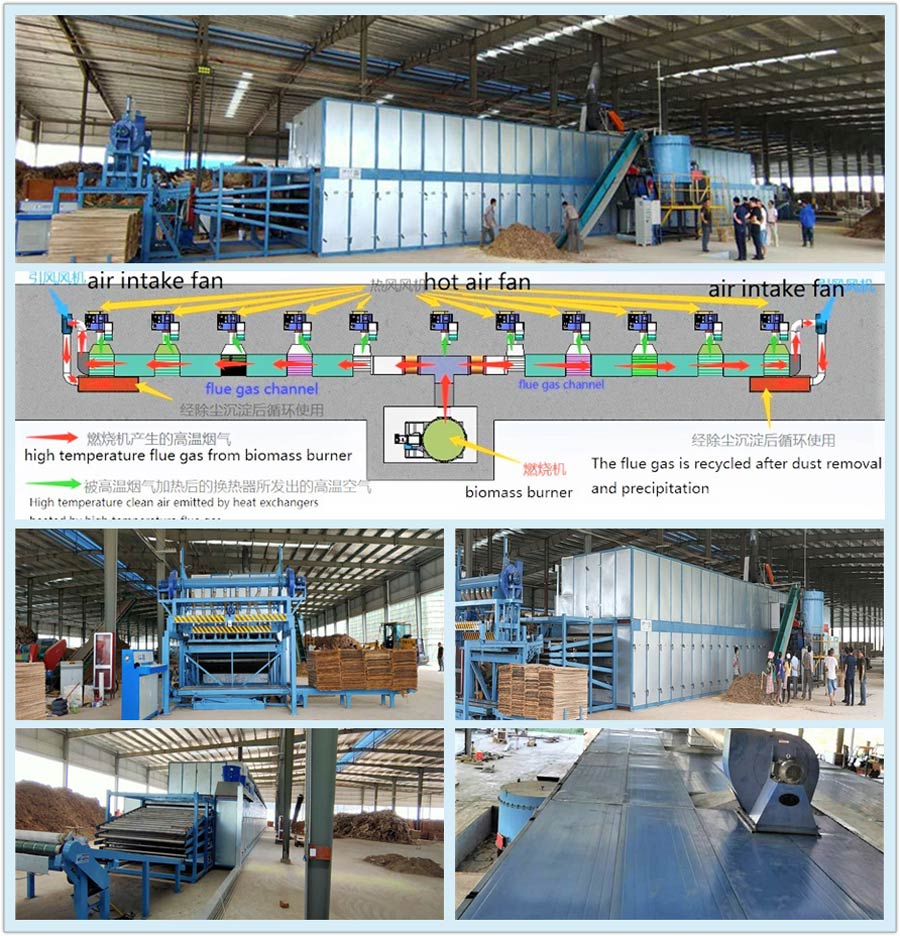

The Veneer Dryer is the most efficient drying method, which can be used to dry all kinds of hardwood and softwood core veneer and face veneer etc. Usually, the biomass-type veneer dryer is divided into a heating section and a cooling section. Shine veneer dryer machine running on biomass burner has the lowest drying cost with high production capacity. This direct heating of hot air causes no heat loss compared to the indirect heating of water or oil. The temperature inside the wood veneer dryer machine is enough to reduce the moisture content to a proper level. The drying cost can be as low as USD 12 per cubic meter.

Product Description of Veneer Dryer

Shine veneer dryer has the bigger veneer drying capacity but at the smallest drying cost. 4 deck Veneer Dryer is equipped with automatic temperature control and speed regulation system, which can accurately control the final moisture content. Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost, and perfect drying effect.

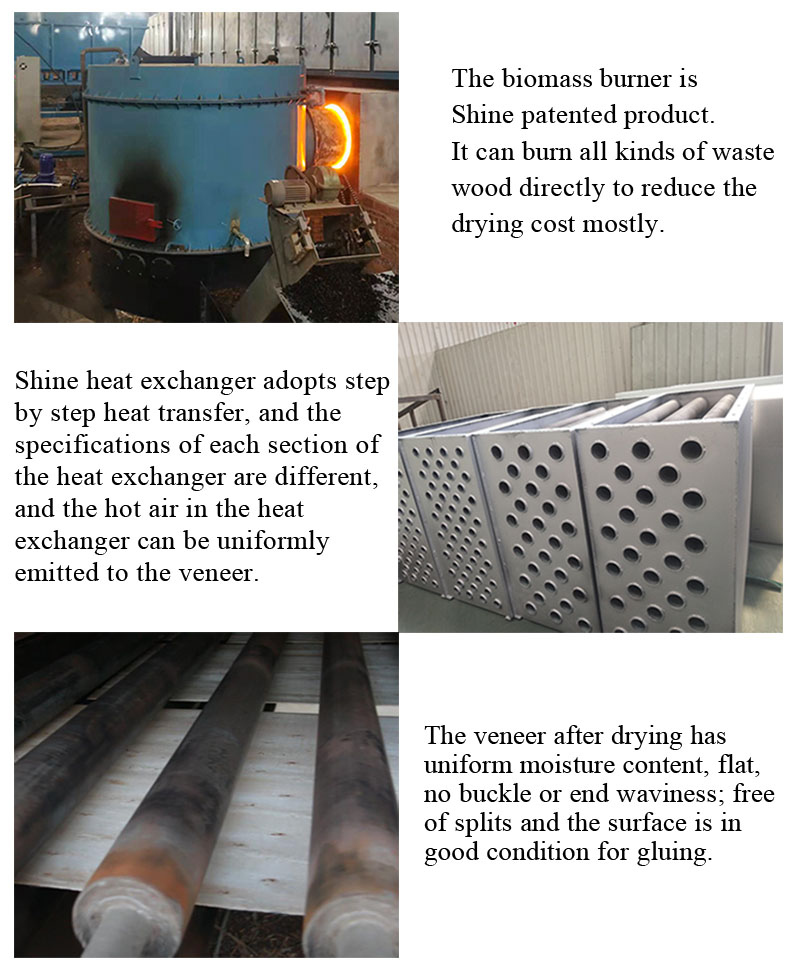

Biomass burner is our patented product, which can save composite costs mostly. The heat exchanger adopts step-by-step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. An automatic feeder and veneer collection system can improve feeding and collecting veneer efficiency and save manpower as well. Shine veneer drying lines can achieve the best drying effect with the lowest cost.

Veneer Dryer in Myanmar

Features of the Veneer Dryer

1. Veneer Dryer has the capabilities of excessive veneer drying productiveness, energy efficiency, lowest drying veneer fee, and best veneer drying effect. the composite walking value is only about USD12/m3, which could enhance clients' earnings space greatly.

2. Custom-designed working width, operating layers, and heating and cooling length of the shine veneer dryer are available in line with customers' specific requirements.

3. Shine machinery is the unique manufacturing facility in china that can make not only veneer dryers but also the heat source of the curler dryer, specifically, biomass burner.

4. Unlike the steam boiler or thermal oil heater which are traditional heat sources hooked up for the dryer, the biomass burner is a specific patented product that can completely burn beaten timber chips, and tree barks without delay as the fuel, fixing the waste accumulation problem inside the veneer and plywood making factories. at an equal time, the fuel price is reduced generally.

5. Expert R&D team can layout special veneer dryer fashions in line with clients' special necessities.

6. Best after-sale provider gadget can ease the mind of patrons after the installation as we deliver 24 online services and far-off operations. Normal observe-up service for antique customers, and enough spare elements supply in time.

Running Video of the Veneer Dryer

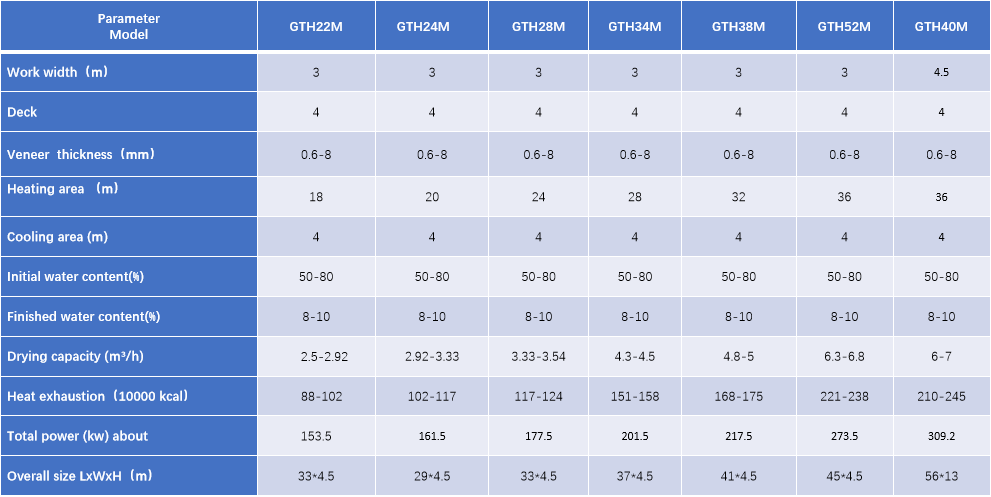

Technical Specifications of Veneer Dryer

Product Details

Certificates of Shine Veneer Dryer

Roller Dryer Worksites

Factory and Workshop

We are very welcome to visit the site and our factory