Wood Vertical Veneer Drying

The wood vertical veneer drying has a uniform airflow, and steady temperature and the countercurrent drying cycle is adopted to ensure that the wood chips are dried quickly and the quality is uniform. Lowest comprehensive veneer drying cost compared with different types of wood core veneer dryers.

Wood Vertical Veneer Drying

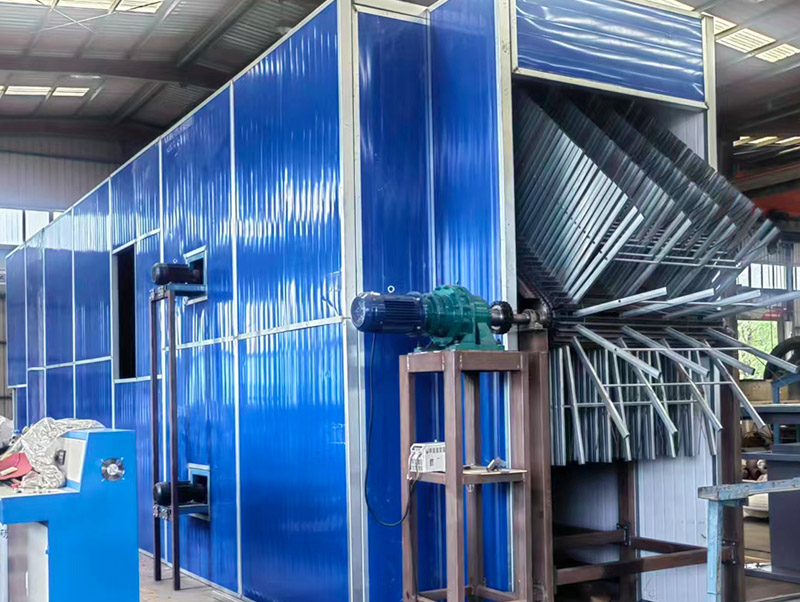

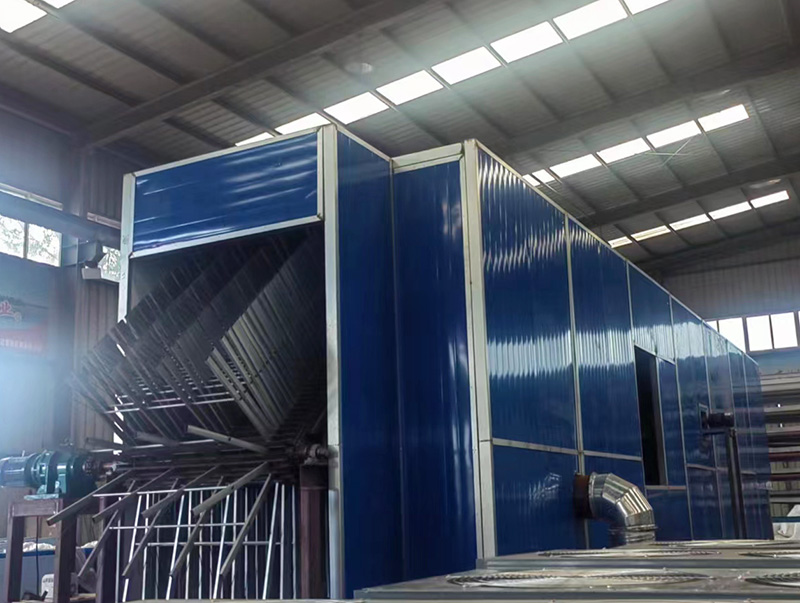

Vertical core veneer dryer machine has a very low purchase cost, and the continuous core veneer drying machine covers a small area, the equipment uses three-dimensional loading of veneer, and the equipment covers an area of only two-thirds of the roller dryer. The equipment has high thermal efficiency and low drying cost. Using the series of supporting products of the company's high-efficiency energy-saving environmental protection heat source, the waste heat reheating technology can be effectively used.

Features of Wood Vertical Veneer Drying

1.The drying cost is low, The drying cost of this vertical dryer is less than $8/M³, which is 30-60% of the drying cost of other dryers;

2.The machine cost is low. Our company has reduced the production loss of raw and auxiliary materials and improved the working efficiency through the standardization and modular production of vertical dryer parts.

3.The drying output is high, and the vertical plywood method increases the loading capacity of the veneer, which is 30-80% higher than that of other dryers;

4.This equipment needs to be assembled on the customer's factory site, so this equipment can be installed according to the customer's specific location requirements.

Product Parameters of Wood Vertical Veneer Drying

Model | FBH30-13 |

Moisture content (%) | fresh veneer dried to 0-5% |

Output (m³/h) | 2 |

Machine size (length X width X height, m) | 13×3×4 |

Hot air fan (KW) | 9(600Wx10) |

Traction motor (KW) | 1.5 |

Induced draft fan (KW) | 3 |

Built-in furnace (KW) | 1.5 |

Total power (KW) | 15 |

Fuel consumption (KG/H) | 200 |

Customer Case

Certification

The Factory

Packaging & Shipping