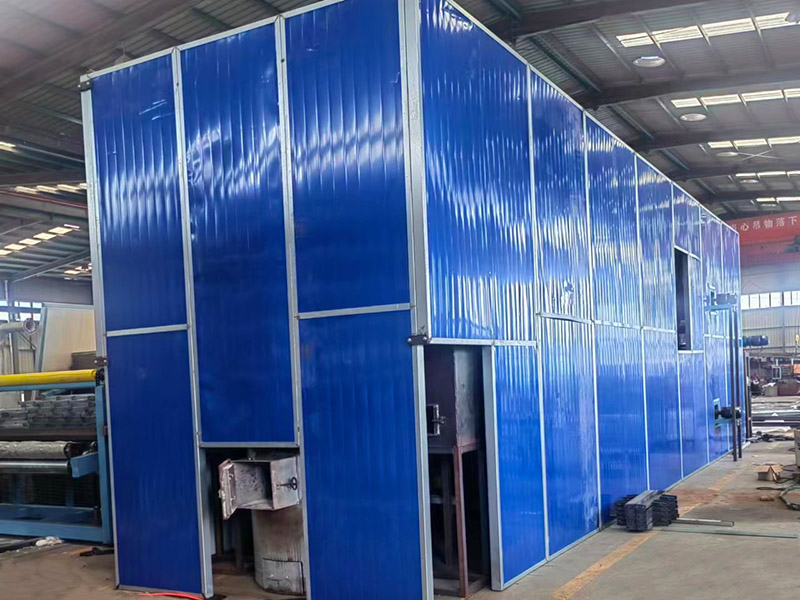

Vertical Dryer Machine

Low cost vertical dryer machine has a very low purchase cost, and the continuous veneer dryer machine covers a small area, the equipment uses three-dimensional loading of wood veneer, and the equipment covers an area of only two-thirds of the roller dryer. The equipment has high thermal efficiency and low drying cost. The vertical veneer dryer has a unique quick-loading structure, and the wood veneer loading speed is fast, which can save labor and cost for the enterprise. With the unique hot air circulation mode inside the equipment, the hot air volume of the drying line is large, and the hot air of each section is hot. The airflow is uniform, the temperature is uniform, and the countercurrent drying cycle is adopted to ensure that the wood veneer are dried quickly and the quality is uniform.

vertical dryer Machine

The Vertical Dryer Machine has a uniform airflow, and steady temperature and the countercurrent drying cycle is adopted to ensure that the wood veneer are dried quickly and the quality is uniform.

Lowest comprehensive veneer drying cost compared with different types of wood core veneer dryers. The wood veneer drying output is high, and the vertical plywood method increases the loading capacity of the veneer, which is 30-80% higher than that of other dryers. The vertical type core veneer dryer equipment cost is low.

Vertical dryer machine: use the chain to bring the veneer or finished board into the drying room for circulating drying.

The vertical dryer machine is a summary of the advantages and disadvantages of many previous veneer dryers after years of market research. Our dryer features:

1. The drying cost is low. The drying cost of this vertical dryer is less than $8/M³, which is 30-60% of the drying cost of other dryers;

2. The machine cost is low. Our company has reduced the production loss of raw and auxiliary materials and improved the working efficiency through the standardization and modular production of vertical dryer parts.

3. The drying output is high, and the vertical plywood method increases the loading capacity of the veneer, which is 30-80% higher than that of other dryers;

4. This equipment needs to be assembled on the customer's factory site, so this equipment can be installed according to the customer's specific location requirements.

Product Parameters of Vertical Dryer Machine

Model | FBH30-10 |

Veneer water moisture | Fresh veneer to about 0-5% |

Drying capacity (m³/h) | 1.5 |

Overall Dimension(L*W*H) | 10X3X4 |

Hot air blower(KW) | 6 (600Wx10个) |

Traction motor(KW) | 1.5 |

Air intake fan(KW) | 3 |

Built-in furnace(KW) | 1.5 |

Total power(KW) | 12 |

Certification

Customer Case

Factory

Packaging & Shipping