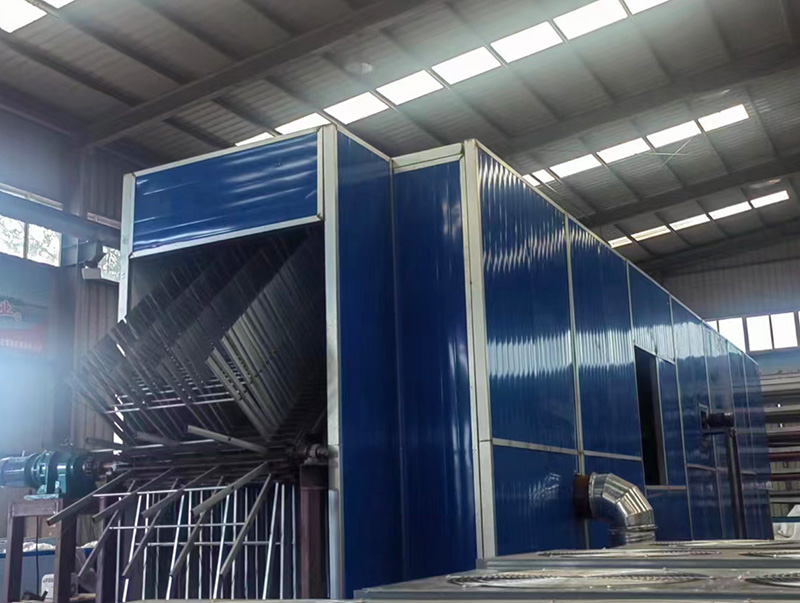

Vertical Veneer Dryer Machine

The vertical veneer dryer machine is an efficient, energy-saving and environmentally friendly wood drying equipment, specially designed for the wood processing industry and wood product manufacturing industry. It dries wood quickly and evenly to the required moisture level, thereby improving wood quality and reducing production costs. Easy to operate, users can easily adjust drying parameters to meet the requirements of different woods.

Vertical Veneer Dryer Machine

The vertical veneer dryer machine can use the chain to bring the core veneer or finished board into the drying room for circulating drying. Energy saving, secondary use of hot air, fast heating, low power consumption, better drying effect, and less maintenance. The veneer tunnel drying machine can be manufactured according to customers' requirements. The veneer drying equipment adopts a co-current drying method. Flue gas and wet materials enter the dryer from the same side, and high temperatures can be used to obtain high evaporation intensity. The dryer outlet temperature is low and the thermal efficiency is high.

If you want to move from natural drying to appliance drying, purchasing a large veneer dryer can be a costly investment. We provide small vertical veneer dryers, allowing you to enjoy lower investment costs in the short term, while also achieving efficient production and profitability, laying a solid foundation for the future of your business.

Product Parameters of Vertical Veneer Dryer Machine

Model | FBH50-20 |

Veneer water moisture | Fresh veneer to about 0-5% |

Drying capacity (m³/h) | 1.5 |

Overall Dimension(L*W*H) | 20X5X4 |

Hot air blower(KW) | 1.5KW*6 |

Traction motor(KW) | 5.5 |

Air intake fan(KW) | 7.5 |

Built-in furnace(KW) | 1.1 |

Exhibition and Customer Visiting

The Factory

Packaging & Shipping