Veneer Roller Drying Machine

Veneer Roller Drying Machine is a new generation wood veneer drying machine. It adopts the latest international pressure contact veneer drying technology to ensure the veneer is heated evenly. It can be used to dry rubber wood, eucalyptus, birch, teak, all kinds of hard wood and soft wood veneer etc.

Product Description of Veneer Roller Drying Machine

Veneer Roller Drying Machine utilizes the latest international technology of pressurized contact veneer drying, which has the advantages of simple operation, safety and practicality, stable operation, easy maintenance, heat pressing- leveling--drying once completed, etc. The roller of core veneer dryer machine plays a role in ironing the veneer. After the veneer is dried, the veneer dried by veneer dryers is flat and the moisture content is relatively uniform. Veneer Roller Drying Machine is popular in South east Asia areas. The composite cost of drying the veneer is only $6-$12 per cubic meter because the biomass burner can provide hot air to burn all kinds of waste wood directly. Good quality wood veneer dryer directly products the best quality of veneer and glued products.

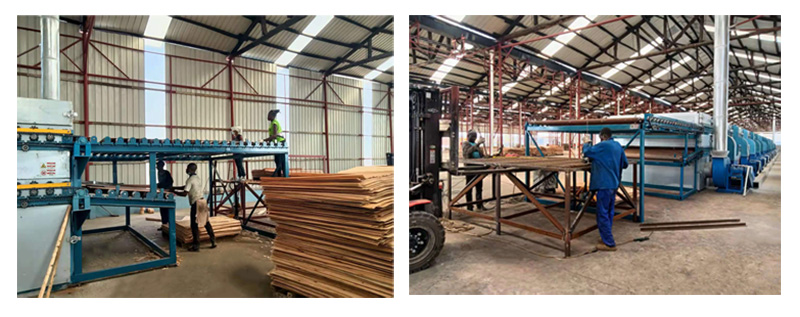

2 Deck Veneer Roller Drying Machine in Congo

Veneer Roller Drying Machine in Congo Customer Factory

Features:

1. This model is a straight-through horizontal circulation veneer roller drying machine.Its thermal cycle design draws on the advantages of advanced European dryer technology,and adopts an upright centrifugal fan with a volute (flow rate of 45,000 to 62,000 m3/ h).

2. The new type of heat exchanger and the rectangular variable-section spray box make the high-speed jet airflow acting on the surface of the veneer uniform.The hot air blowers in the heating chambers in the front and rear areas are arranged separately from left to right,so as to ensure that the dried veneer obtains a consistent final moisture content at each point.

3.In order to adapt to the humid tropical climate,the length of the cooling open section is appropriately lengthened to facilitate the cooling of the dried veneer and reduce the phenomenon of damp return.

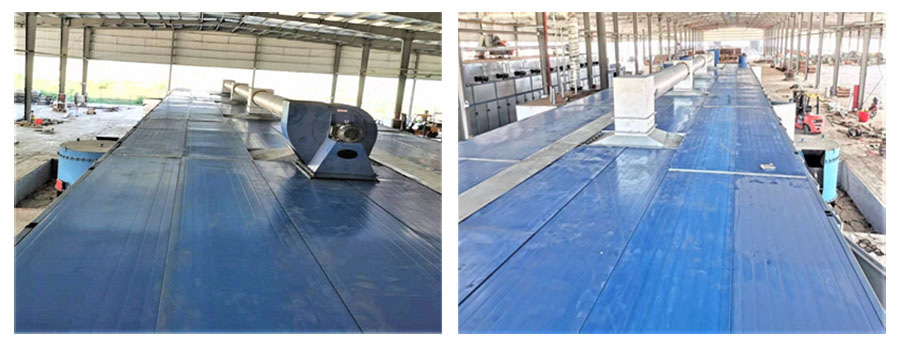

Parts of Veneer Roller Drying Machine

2 Deck Veneer Roller Drying Machine

Product Parameters of Veneer Roller Drying Machine

Model No | GTH30-56 |

Working Width | 3m |

Deck | 2 |

Heating area length | 52m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 85-95cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:11KW(13pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 11KW(1pc) |

Air intake fan | Power : 15KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 215.5KW |

Actual electricity consumption | About 150kwh per hour |

Project Case

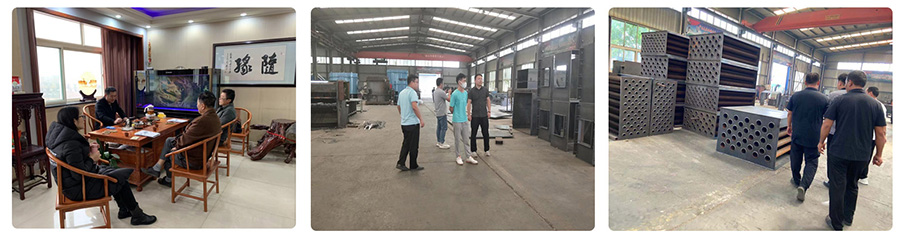

Our Factory

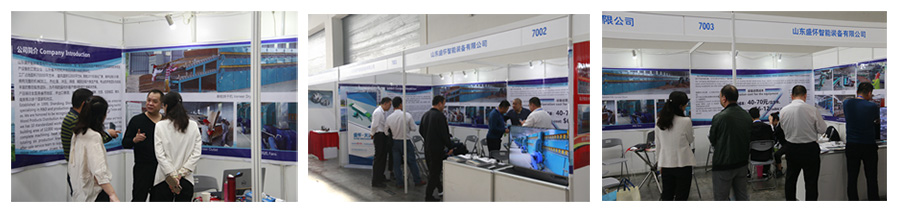

Customer Visiting and Exhibition

Our Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation