Smart-Control Plywood Veneer Dryer

Shine biomass veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. It has been exported to more than 100 countries and regions, and has agents in more than 50 different countries. Users can visit the project case scene nearby. Compared with the traditional dryer, the post-operation cost is reduced by 35-40%.

Shine plywood veneer dryer is of high quality and efficiency and is the best choice for plywood veneer drying.Roller type wood veneer dryer can keep the veneer smooth and has uniform moisture content after drying. The output of veneer with the thickness of 0.5-5mm through veneer drying machine. Waste wood and other waste bark can be used as the fuels for thiccoreveneer drying line, saving the cost significantly. The composite cost is about only USD 6-12/cubic meter. Our biomass burner of plywood veneer dryer can use waste wood as fuel ,which is environmental,saving energy,reduce cost and also there is no any smoke.

The plywood veneer dryer has a variety of different drying configurations to suit a variety of drying needs are available. The length, width, and layers of the core veneer dryer can be designed and made for customers. The veneer roller dryer machine is durable in use and long service life. Shine Machinery is responsible for providing users the best drying solutions, not just the veneer dryer itself to ensure the higher drying capacity, energy efficiency, and less fuel cost. In line with the specific production capacity, the wood veneer drying machine can be customized to meet customers' needs.

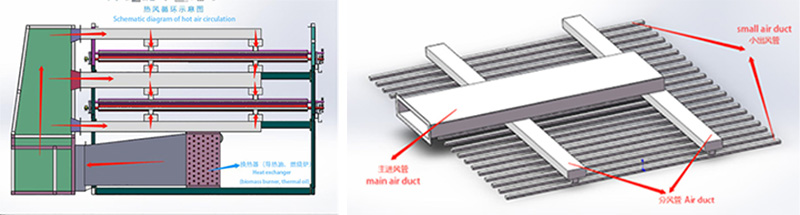

Heat Exchange System and Hot air Circulation System

Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and The hot air exchanges heat through the heat exchanger and distributes it evenly to the veneer. The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

Automatic Electric Control and Frequency Conversion System

Shine veneer dryer adopts automatic electric control and frequency conversion system, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve and ideal drying effect.

Product Parameters of Plywood Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

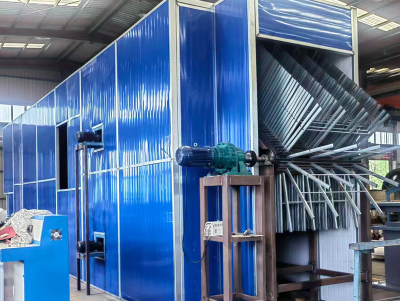

The installation

Customer Case

The Factory

Packaging & Shipping