2 Deck Veneer Core Dryer Machine

2 Deck Veneer Core Dryer Machine is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad.We have a professional R&D team that can design different models according to customer’s special requirement.Shine Veneer Dryer is the most economical dryer available because it consumes much lower power as compare to the any other brand.Our Jet Ventilated Roller Track Veneer Dryer can run on Steam as well as Thermic Fluid.

Product Description of 2 Deck Veneer Core Dryer Machine

2 Deck Veneer Core Dryer Machine is a very important machine in the plywood making process.The moisture content after veneer drying is uniform and veneers are in good condition before gluing.The veneer dried by roller dryer is flat,no buckle or end waviness.Shine 2 deck veneer core dryer machine is widely valued for the lowest operation cost,high drying capacity,and energy-efficient as well as high-quality veneer output.It is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad.The composite cost is only about $6-12/cubic meter fuel cost and electricity power.

2 Deck Veneer Core Dryer Machine in Congo

2 Deck Veneer Core Dryer Machine in Indonesia

2 Deck Veneer Core Dryer Machine in Zimbabwe Customer Factory

Veneer dryer chain, Roller running veneer, Outfeed

Features:

1.The machine is the main apparatus in plywood industry.

2. It uses to remove moisture from the veneer.

3.The heat medium can be thermo oil ,Biomass burner and heat steam.

4.The whole machine can be divided into two parts: heating section and cooling section.

5.It includes mesh type, roller type, could be customized according to your requirements.

Video

2 Deck Veneer Core Dryer Machine

Product Parameters of 2 Deck Veneer Core Dryer Machine

Model No | GTH30-48 |

Working Width | 3m |

Deck | 2 |

Heating area length | 44m |

Cooling area length | 4m |

Veneer thickness | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200℃C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 70-80cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:11KW(11pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 11KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 185.5KW |

Actual electricity consumption | About 130kwh per hour |

Parts of Veneer Dryer and Project Case

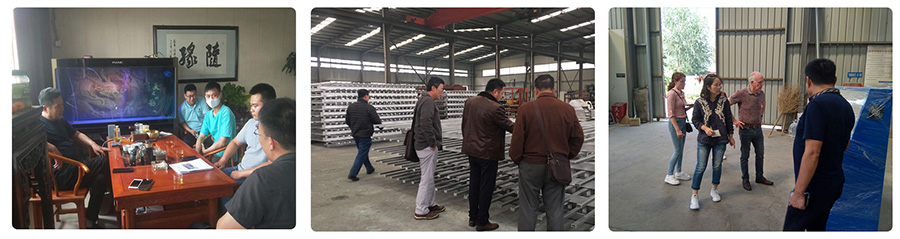

Our Factory and Customer Visiting

Customers from all over the world visit

Our Certificate

FAQ

Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machines by ourselves.

Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paid against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 50 countries customer.