Veneer Drying

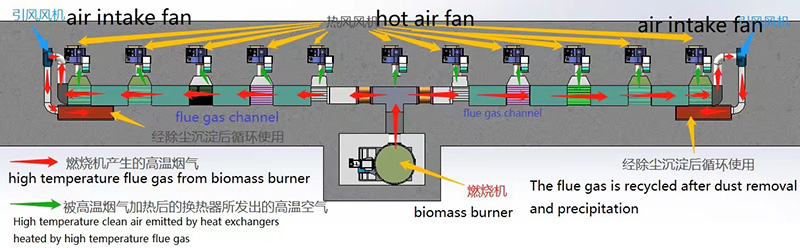

Continuous veneer drying has the characteristics of high efficiency, energy saving, and low operating cost. Shandong Shine's biomass burner with patented technology burns waste wood and saves fuel costs. With a complete veneer in feeding system, hot air circulating system, veneer out feeding system, auto temperature and speed regulation system, and humidity removal system, the veneer dryer operation is more efficient.

Type: Roller Veneer Dryer

Working Width: 4.5m

Veneer thickness: 0.8-8mm

Heating Area Length: 36m

Drying capacity (m³/day) : 180

Veneer Water Moisture: Fresh veneer to about 0-15%

Cost: 6-12$/m3 (Labor+Fuel+Electricity)

Heat Source: Biomass Burner (Other options available)

Shine extensively applies low-carbon technology in its roller veneer dryers, employing an efficient heat recovery system, which greatly improves energy utilization efficiency. This practice has received wide acclaim from our customers.

Here is one of the repeat purchases from an Industrial Park in Thailand. Shine meticulously configured the equipment based on the customer's overall requirements. This set of equipment is equipped with a semi-automatic loading system and a semi-automatic unloading system. The customer utilizes thermal oil as the heat source. Drawing from our extensive experience in researching and incorporating low-carbon technology into product design and manufacturing processes, Shine suggested the installation of a water film dust removal device for the customer.

The hot air blower and cold air blower of the veneer drying adopt the latest axial flow blower, and the power of the whole machine is reduced by 35%, which not only fully guarantees the air volume required for drying, but also reduces the total installed power and minimizes the power consumption of the entire equipment.

Product Parameters of Veneer Drying

Model No | GTH45-40 |

Working Width | 4.5m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 180-200 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 8KW(18pc) |

Traction motor | Power: 7.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 11KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 228.5KW |

Actual electricity consumption | About 160kwh per hour |

Overall Dimension(L*W*H) | 51m×13m×3.5m |

Certification

Customer Case

Packaging & Shipping