Plywood Veneer Dryer

Shine customers come from more than 100 countries around the world. Due to the use of an axial fan, The power is half lower than the traditional dryer, and the automation is high (can be equipped with automatic feeding system and collection system). Late stage drying costs are 20% lower than traditional dryers.

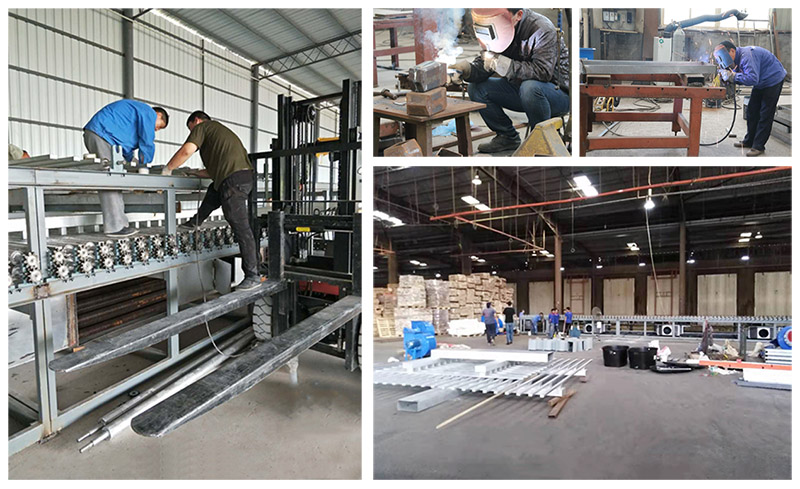

R&D personnel: 50 people, production personnel: 100 people, the factory covers an area of 12,000 square meters.

It has 150 sets of various equipments and 6 complete production lines including machining, heat treatment, stamping, welding, assembly and painting.

24 hours online service (WhatsApp: 15806625431)

Product Description of plywood veneer dryer

4 deck plywood Veneer Dryer is our main product for high-end customers to meet the higher capacity requirements of customers, which has the salient features of higher drying capacity. The rollers use φ102 steel special shaft tube. The bearings of the 4 deck plywood veneer dryer are featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance which no need injecting oil and easy maintenance in the daily operation.

Plywood Veneer Dryer Video of Customer Factory

Our Latvian customer has ten years of experience in the use of veneer dryers. He used to buy machines from other manufacturers. Later, the customer was very interested in the technology of our equipment. After repeated negotiations and negotiations, the customer finally purchased our Veneer dryer. After using the comparison, customers give positive evaluation to our equipment. "The dryer produced by Shine is more cost-effective than European and American brands, and the drying effect of the veneer is better!" said the customer.

We have also provided customers with a 24-hour uninterruptible power supply to avoid the machine stopping operation during the power outage and affecting the drying output.

The plywood veneer dryer purchased by our Latvian customer is a 4-layer 38-meter plus 10-ton biomass burner (maximum heat generation of 6 million calories per hour, which can directly burn all kinds of waste wood), equipped with automatic feeding system and The collection system, coupled with the water film dust removal system, The exhausted flue gas complies with European environmental protection requirements.

Our veneer dryer can not only dry the first class board and the second class board and the third class board, and some small defective boards can also be dried. And our new dryer has 40-50% less power than traditional dryers, which greatly reduces operating costs.

The customer used it very well and was quite satisfied. Later, he signed two sets of equipment with 4 floors and 38 meters with us.Customers around Latvia are welcome to visit the equipment site at any time.

The automatic board feeding, board separation system and automatic board collection system are the first automatic board feeding and board collection systems for plywood veneer dryer in China. Only 1-2 people are required to be on duty at both ends of the dryer, which solves the problem of manual board feeding personnel. The problem of large number and high labor intensity. Full automation from board entry to board collection. Our dryer is not easy to block the board, high efficiency and energy saving,The company has a long time in the drying industry, rich experience, Received more than 20 technological innovation awards, and after-sales guarantee.

Three-stage dust reduction system: After passing through the three-stage dust reduction inside the burner, the flue and the dust collection box, the discharged flue gas will not cause environmental pollution.

Product Parameters of Plywood Veneer Dryer

Model No | GTH30-38 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 34m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(34pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

10ton biomass burner | Power: 16.5KW |

Total power | 228.5KW |

Actual electricity consumption | About 160kwh per hour |

Project Case

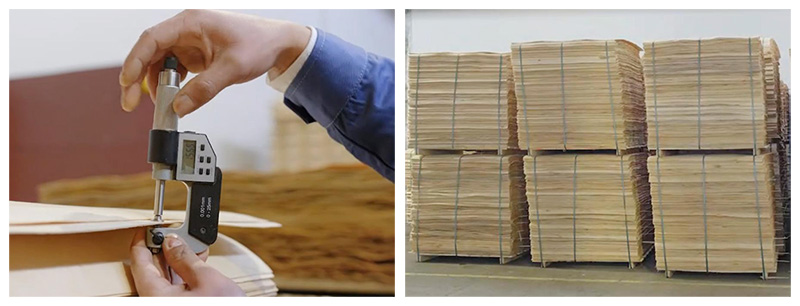

Certification

Customer Visiting and Factory

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood veneer dryer

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service(WhatsApp:15806625431)

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging(Technical phone:+8615665878109)Door to door service is possible

Product Packaging And Transportation