Roller Core Veneer Drying Machine

Roller core veneer drying machine can keep the veneer smooth after drying. veneer dryer machine equipped with water circulation system, which can save energy and improve efficiency. Biomass burner as heat for 40m 4 deck roller core veneer drying machine, bark and other tree waste can be used as the fuels for veneer drying line, saving fuel cost significantly. biomass veneer drying machine is only USD 6-12/per cubic meter.

Veneer thickness: 0.6-0.8

Veneer water moisture:Fresh veneer to about 8-10%

Drying capacity (m³/h):8

Product Description of Roller core veneer drying machine

Working Principle: The veneer is clamped by the upper and lower seamless steel tube rollers, and the oven temperature reaches 140 ℃ by preheating, and then enters between the upper and lower rollers and blows high pressure hot air to the upper and lower sides of the veneer through the hot air pipe for rapid drying.

Shine roller core Veneer Drying machine has the features of high veneer drying productivity,energy efficiency, lowest drying veneer cost and perfect veneer drying effect.The composite running cost is only about $12/cubic meter,which can improve customers' profit space greatly.

4 deck veneer dryer in Latvia

roller core veneer drying machine

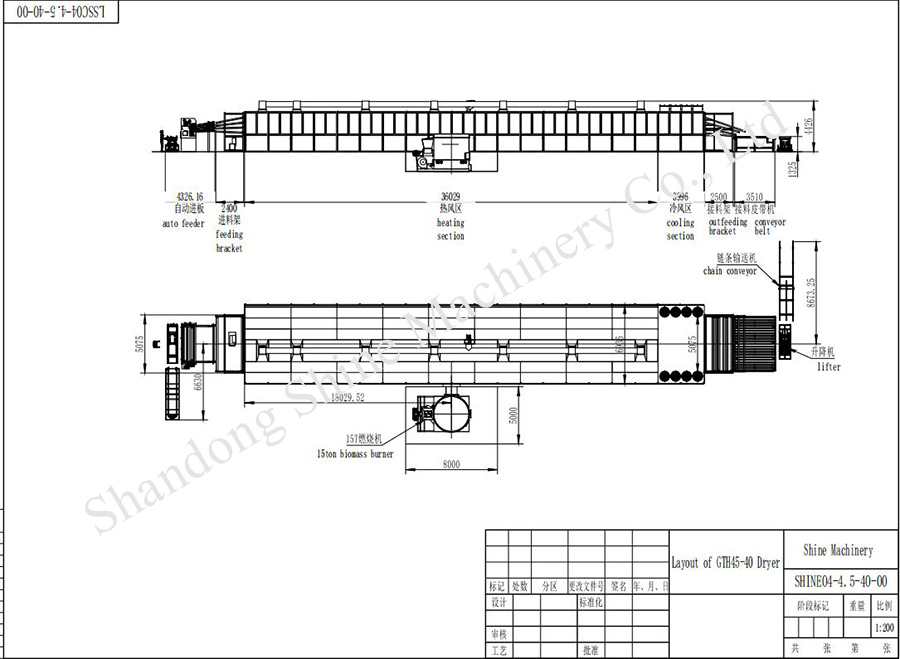

Layout Drawing of veneer dryer model GTH30-40

Product Parameters of Roller Core Veneer Drying Machine

Model No | GTH45-40 |

Working Width | 4.5m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 8 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 11KW(18pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

15ton biomass burner | Power: 16.5KW |

Total power | 290.5KW |

Actual electricity consumption | About 200kwh per hour |

Running Video of the Roller Core Veneer Drying Machine

Features:

1.The machine is the main apparatus in plywood industry.

2. It uses to remove moisture from the veneer.

3.The heat medium can be thermo oil and heat steam.

4.The whole machine can be divided into two parts: heating section and cooling section.

5.It includes mesh type, roller type, mesh&roller type, could be customized according to your requirements.

Customer Case

roller core veneer drying machine of Indonesia customer

Our Certificate

Our Services

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Product Packaging And Transportation