20m Automatic Veneer Dryer Machine

Shine 20m automatic veneer dryer machine is our high-end veneer drying machine with the salient features of bigger drying output. Maximum veneer drying capacity can reach around 200m3. The rollers use φ102 seamless steel pipe. The bearings of the 4 deck 20m automatic veneer dryer machine featured high temperature 500 degree Celsius resistance and low temperature of -20 degree Celsius resistance. which no need to inject oil and easy maintenance in the daily operation.

Product Description of 20m automatic veneer dryer machine

Shine 20m automatic veneer dryer machine is our high-end product specially designed to meet the bigger veneer drying capacity requirements of customers with the salient features of bigger drying capacity and automatic veneer in feeding and out feeding systems. The rollers use φ102 special shaft tubes. The bearings of the 4 deck 20m automatic Veneer Dryer machine featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance, which no need to inject oil and easy maintenance in the daily operation of the wood core veneer dryer. An automatic feeder and veneer collection system are installed for the veneer drying machine. Only need 1-2 people at both ends of the dryer, which solves the problem of high labor intensity.

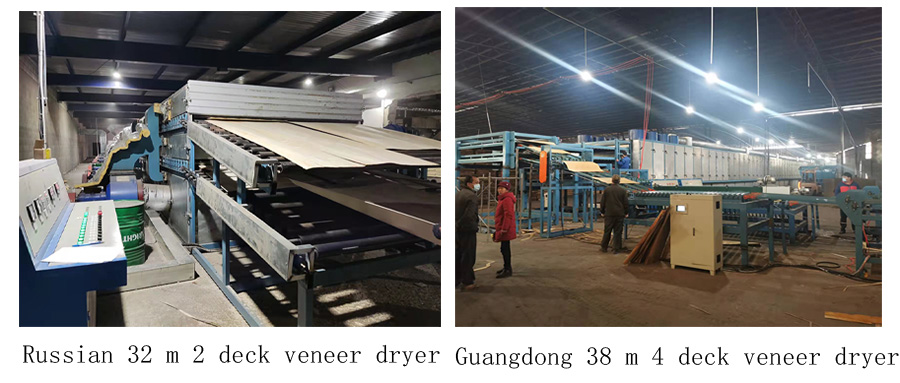

4deck 20m automatic veneer dryer machine in Latvia

Veneer Dryer in Myanmar Customer's Factory

Biomass Burner Veneer Dryer machine

Veneer dryer chain, Roller running veneer, Outfeed

Advantages of 20m Automatic Veneer Dryer Machine

1. Jet nozzles box/hot air tubes: made of high-quality galvanized plate, the overall shape is a variable section, the working surface is corrugated orifice plate, the width of the jet nozzles/hot air tubes is 200mm, and the thickness of the steel plate is 1.0mm galvanized sheet.

2. Insulation board: The thickness of the side insulation board is 80mm, and the panel is 1.2mm galvanized sheet, lined with aluminum silicate blanket. The thickness of the top insulation board is 75mm, and it is lined with rock wool composite board.

3. Shine veneer dryer is equipped with automatic temperature control and speed regulation system, which can accurately control the final moisture content. Avoid the phenomenon that a large number of veneers are over-dried or do not meet the process requirements.

4. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

5. Traction motor: domestic high-quality electromagnetic speed-regulating motor and governor.

6. Electric control system: The main electrical components are all domestic brands. The control cabinet has a reasonable layout, beautiful appearance and easy operation.

7. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output greatly.

8. The biomass burner developed by our company, which can use the black skin, white skin, saw head and other waste wood produced by the veneer rotary cutting as fuel, which can obtain materials on site and turn waste into treasure. It greatly reduces the energy cost in the drying process of the veneer, and is a truly energy-saving and environmentally friendly heating device for the dryer.

9. Less maintenance is required for Shine veneer dryer and no veneer jamming/clogging leading to lesser downtime.

Video of the 20m Automatic Veneer Dryer Machine

Technical Parameters of 20m Automatic Veneer Dryer Machine

Model No | GTH30-20 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 16m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 2.5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(16pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(1pc) |

6 ton biomass burner | Power: 16.5KW |

Total power | 145.5KW |

Actual electricity consumption | About 100kwh per hour |

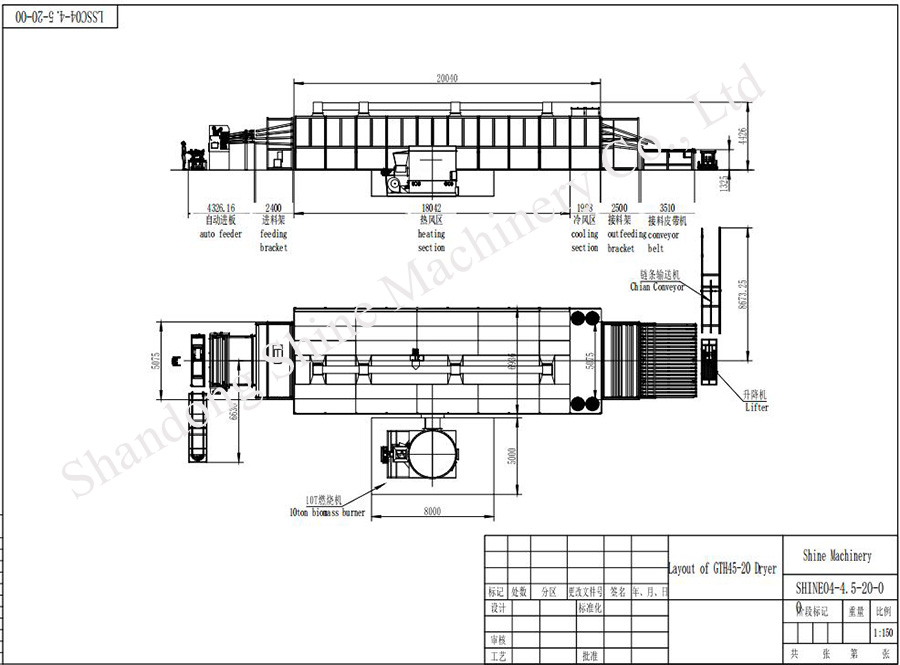

Layout Drawing of 20m Automatic Veneer Dryer Machine

Project Case

Parts of Veneer Dryer

Customer Visits

Customers from all over the world visit

Certificates

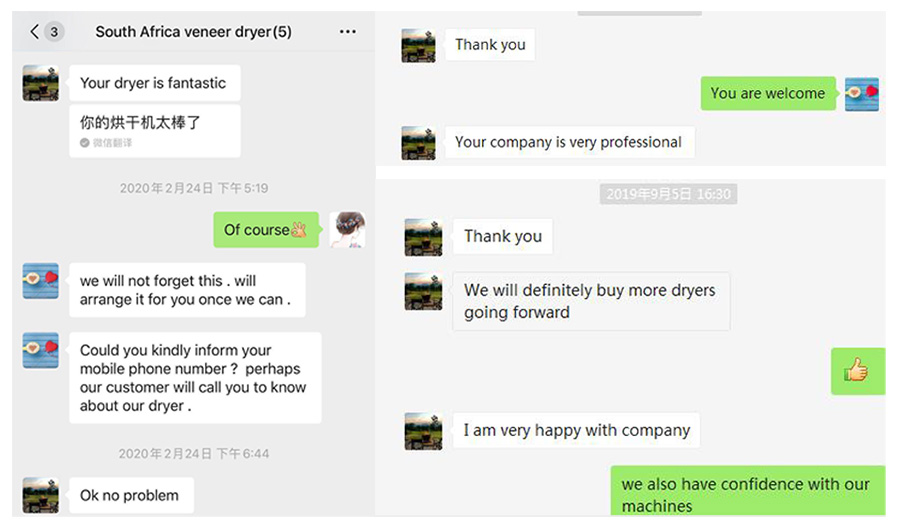

Customer Feedback

FAQ

1. How much does it cost to dry 1m³ veneer?

About $12, including labor, fuel, and electricity, will fluctuate with local prices.

2. How to choose a product that is most suitable for me?

A: Our company has professional engineers to select the most suitable product according to your capacity and areas, saving your time and cost.

3. Will it be difficult to install?

A: We will send professional engineers to guide. In remote situations, engineers will video assist workers with installation. There are many remote success stories.

4. Can I see the real equipment and factory?

Yes. We can provide the location of our veneer dryers that have been put into production, and we contact and communicate with the users for you. Hence you can see the working conditions of our roller dryer machine.