3 Deck Biomass Heated Veneer Dryer

3 deck biomass heated veneer dryer is widely valued for the lowest operation cost,high drying capacity,and energy-efficient as well as high-quality veneer output.It is meant for drying the Core Veneer & Face Veneer and is the Dryer of choice all over the country as well as abroad.The composite drying cost of biomass veneer dryer is about $6-12/cubic meter,including the labor cost,fuel cost and electricity power.

Product Description of 3 Deck Biomass Heated Veneer Dryer

3 deck biomass heated veneer dryer runs without thermal oil heater or steam boiler. It uses waste wood fired air heater/ Biomass Burner which is our new patented product. It eliminates heat loss by directly heating air and supplying to the dryer instead of indirect heating of Oil or water. As the waste wood, waste veneers, tree barks, rind, chips, etc. are the most cost economical fuel compared to the coal, gas, steam or oil and the burning temperature is high enough to dry veneer to a right moisture content level, the shine veneer roller dryer has the lowest drying cost. The temperature in the biomass burner is up to 800 degree celsius and 140-200 degree celsius in the heating section of the dryer, which is enough temperature to remove the extra moisture out of the green veneer.

3 deck biomass heated veneer dryer in Myanmar

3 Deck Biomass Heated Veneer Dryer

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment

7.Provide technical exchanging

8.Door to door service is possible

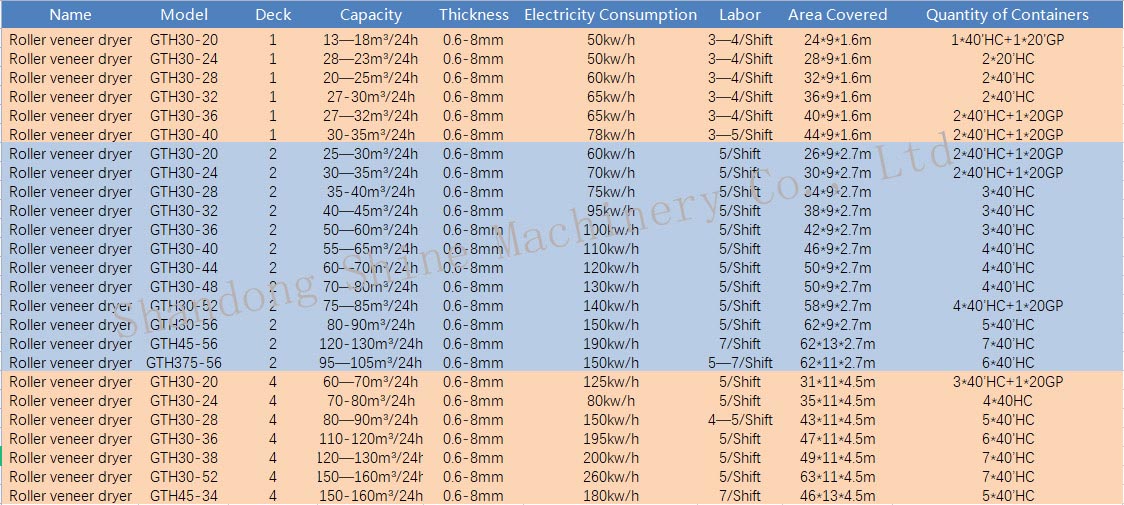

Product Parameters of 3 Deck Biomass Heated Veneer Dryer

Our Factory

We are very welcome to visit the site and our factory

Our Certificate

Product Packaging