core veneer dryer for plywood

The veneer dryer minimizes energy consumption and saves costs for your production process. Through precise temperature and humidity control, the effect of the veneer during the drying process is ensured. The automated control system improves production efficiency. SHINE provides you with customized veneer drying solutions. If you want to know more details about the machine (performance, detailed parameters, videos, etc.), please contact us(WhatsApp: +8615806625431)

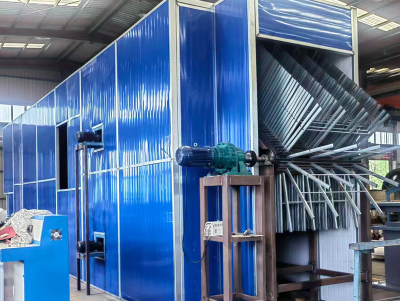

Core Veneer Dryer for Plywood

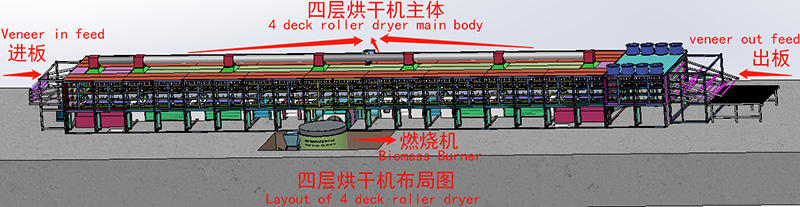

The 4 deck Veneer Dryer has a 38% lower power consumption, uses a new axial flow fan, and can select the degree of automation (Manual feeding, semi-automatic and fully automatic veneer feeding and collecting systems). It is highly efficient and energy-saving, and the boards are flat and wrinkle-free after drying.

Heat source: biomass burner, thermal oil furnace, natural gas, steam and other heat sources.

We provide a variety of customized design solutions and customize veneer dryers according to your specific needs. Whether it is a large or small scale production, we can tailor a veneer drying solution for you. From equipment selection, installation and commissioning to after-sales service, we provide a full range of one-stop services.

Product Parameters of Core Veneer Dryer

Model No | GTH30-44 |

Working Width | 3m |

Deck | 4 |

Roller material | Q235B, φ 102 special shaft tube |

Heating area length | 40m |

Cooling area length | 4m |

Veneer thickness and size | 1mm;1.2mm;2.4mm;3.5mm(2570*1370mm) |

Veneer water moisture | Fresh Veneers (above 70%) to about 10% |

Heating material | Thermal Oil |

Drying capacity | Minmum 125m³/day, Maximum 140m³/day

(with 24 working hours) |

Veneer transport speed | 5-22m/min, 16A chain |

Power of Hot Air Blower | 4kw (40pc) |

Power of Traction Motor | 5.5kw, frequency control (4pc) |

Power of Cold air blower | 4kw (4pc) |

Total Power | 198kw |

Actual electricity consumption | About 135kwh/ hour |

Overall Dimension(L*W*H) | 50m×4m×5m |

The Factory

Packaging & Shipping