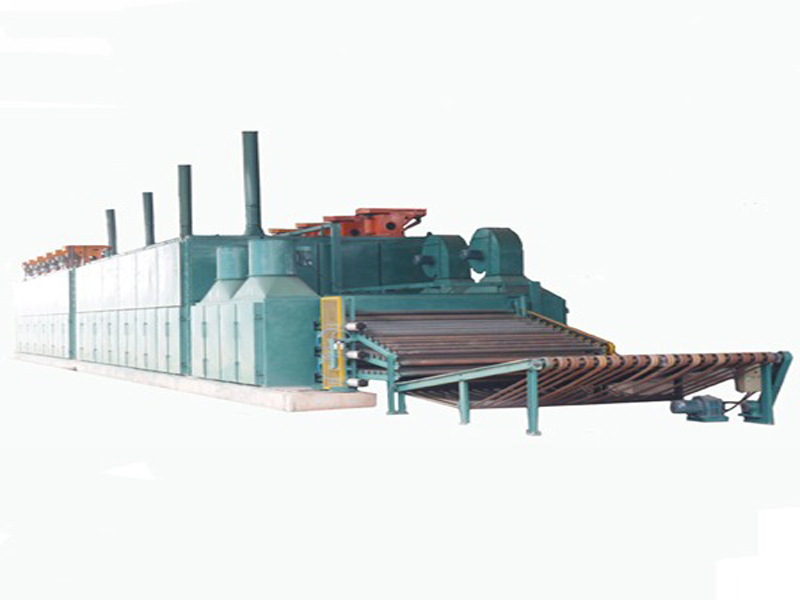

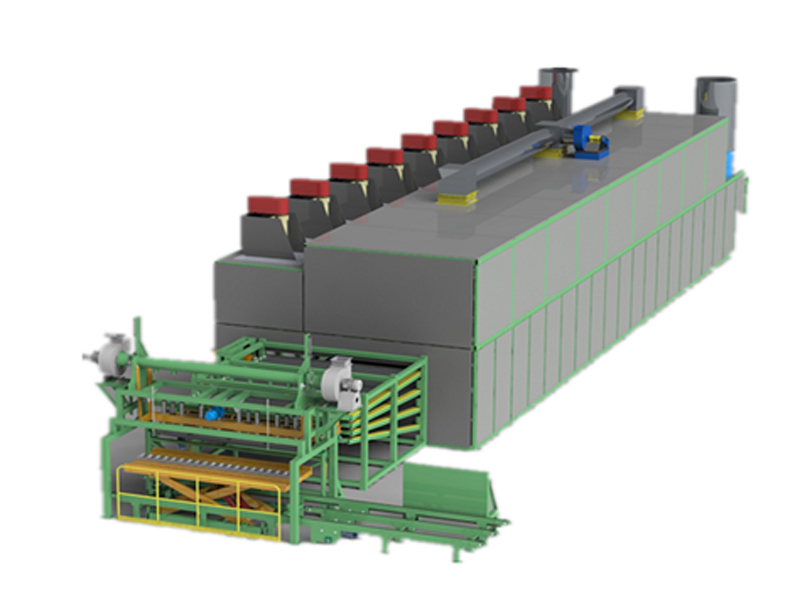

Natural Gas Heated Veneer Dryers

1. To dry one cubic meter veneer needs about 40m3 natural gas.

2. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

3. The control cabinet has an automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

4. No need steam boiler or thermal oil heater any more. Direct burning natural gas to heat air eliminate heat loss for the veneer dryer.

Product Description of Natural Gas Heated Veneer Dryers

Natural Gas Heated Veneer Dryers are widely used where fire is strictly forbidden.In the real veneer production,natural gas dryers are used for veneer drying for plywood.In the gas dryer the drying agent is heated by natural gases combustion.Furthermore,in the gas dryers,the veneer is dried under severe conditions;the drying temperatures are high,which significantly shortens the drying time.

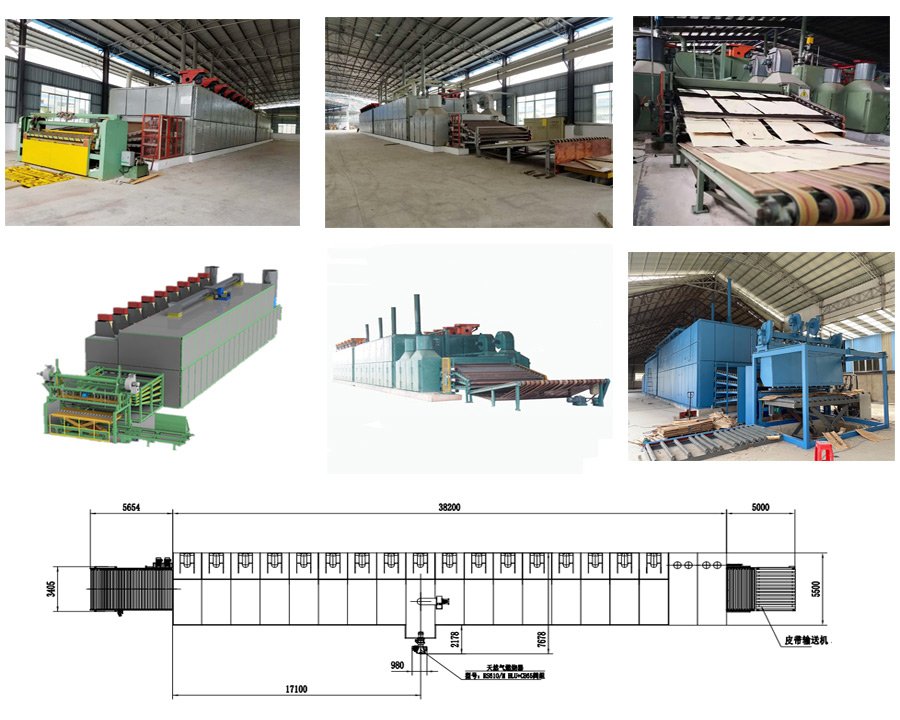

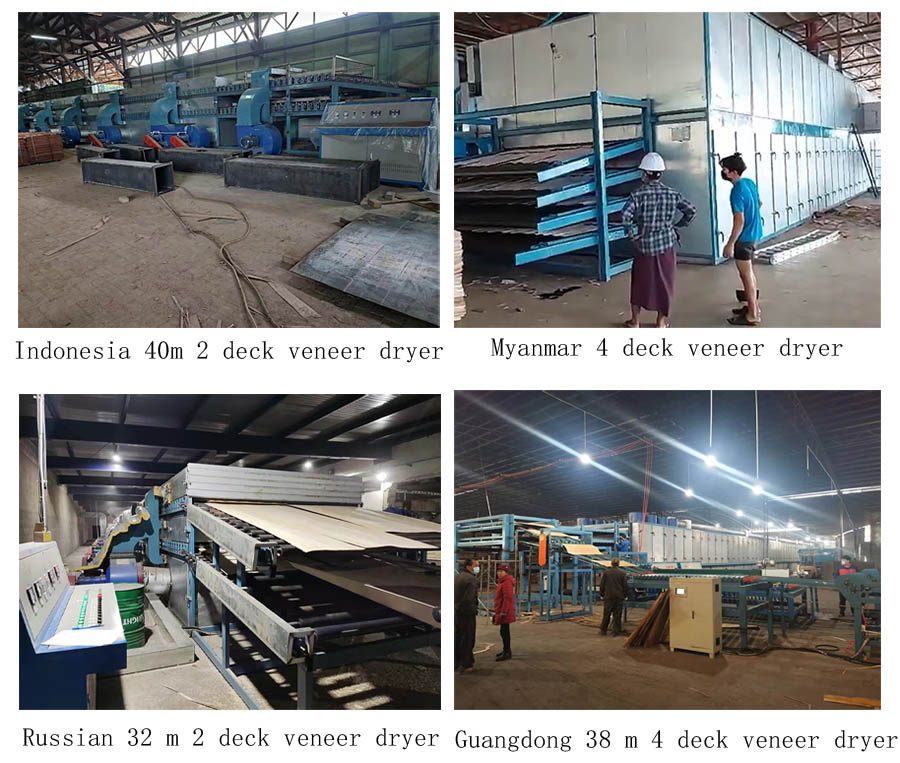

veneer roller dryer in Myanmar

Veneer Dryer in Thailand Customer's Factory

Features of the Natural Gas Heated Veneer Dryers

1.Natural Gas Heated Veneer Dryers is one of the traditional veneer dryer types.

2. The drying temperature is higher and greatly shortens the veneer drying time.

3. It is clean energy which means no air pollution concern.

4. The natural gas burning device can do high precise control the drying temperature.

5. No need for indirect heating of steam boiler or thermal oil heater anymore. Direct burning natural gas to heat air eliminate heat loss for the veneer dryer.

Video of the Natural Gas Heated Veneer Dryers

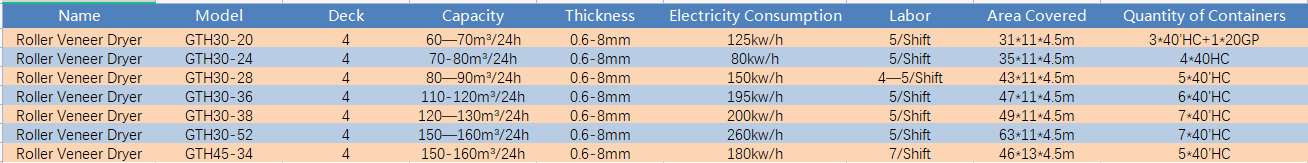

Technical Parameters of Natural Gas Heated Veneer Dryers

Customer Case

Quality Certificates of Natural Gas Heated Veneer Dryers

Veneer Dryer Shipment

Shine Factory and Workshop

We are very welcome to visit the site and our factory