30 m 3 Deck Veneer Mesh Belt Dryer

veneer mesh belt dryer is a professional drying machine specially for the face veneer thickness 0.2-0.4mm.It is a very good dryer machine for the face veneer making factory.Usually the continuous veneer ribbon is dried firstly and then cut into required size to get the biggest yield.The face veneer after drying has the uniform moisture content,flat with no buckle or end waviness.The surface is in good condition before gluing into plywood.

Product Description of 30 m 3 Deck Veneer Mesh Belt Dryer

30 m 3 deck veneer mesh belt dryer is important machine in plywood processing. When you peeling get fresh veneer, for long stock, need remove water and moisture, so you need core veneer dryer or drying line. Shine 3 deck veneer dryers have the salient features of higher price performance ratio, higher drying capacity. 30m 3 deck mesh belt dryer is suitable for drying thin face veneer, which can dry about 2.7m³ veneer per hour. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

30 m 3 Deck Veneer Mesh Belt Dryer in customer factory

3 Deck Veneer Mesh Belt Dryer

Advantages of 3 Deck Veneer Mesh Belt Dryer

1. Drying slicer veneer, stay log lathe/half round slicer veneer, rotary peeling face veneer.

2. Reliable operation, longer service life, energy efficient and unmatched performance.

3. The equipment is flexible in configuration, and there are many materials for drying at one time, and it can be continuously produced and dried, which is convenient to use and greatly reduces labor.

4. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

5. Less maintenance is required for this type of dryers with no veneer jamming leading to lesser Downtime.

Video

30 m 3 Deck Veneer Mesh Belt Dryer

Product Parameters of Veneer Mesh Belt Dryer

Model No. | WDH-31-30 |

Working Width | 3100mm |

Layers | 3 decks |

Heating Section | 14 sections×2000mm=28000mm |

Cooling Section | 1 section×2000mm=2000mm |

veneer feeding section | 9000mm |

veneer discharge section | 9000mm |

Total Power | 131.5KW |

Transmission Motor | 7.5kw×3 pcs=22.5kw frequency control |

hot air fan | 7.5kw×14pcs=105kw |

Cold air fan | 4kw×1pc =4kw |

Radiator | 14 units L 2000mm×W 300×H 900mm |

Transmission speed | 1-30m/min |

Heating Medium | Waste wood burner |

Drying temperature | 150-180℃ |

Thermal energy consumption | 240 X104 Kcal |

Drying Thickness | 0.2-6mm |

Initial moisture content | -50% |

Final moisture content | 10±2% |

Drying capacity | 1.2-2m³ |

Mesh belt material | Galvanized steel infrared photoelectric off tracking |

mesh | 25×32mm |

Mesh belt length | Length 400m X Width 2.7m |

Roller diameter | 89mm |

Roller Space | 1000mm |

Roller Quantity | 120pcs |

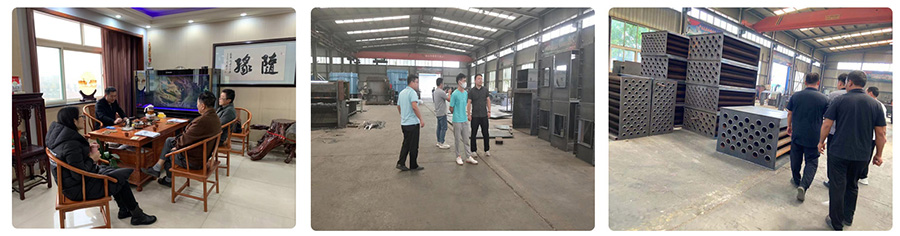

Customer Visiting

Customers from all over the world visit

Our Certificate

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment

7.Provide technical exchanging

8.Door to door service is possible