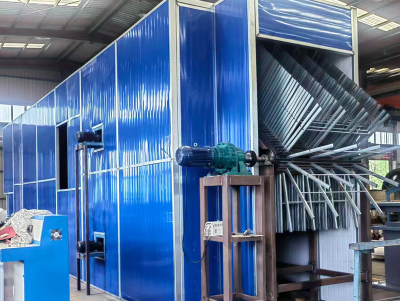

Professional Veneer Drying System

1. Customizable (customized one-stop service)

2. Professional factory production

3.Energy saving and power saving, using axial flow fans, the power of the whole machine is reduced by 38%

4.The main electrical components are all well-known domestic and foreign brands

5.Convenient installation (installation can be completed in 25-30 days)

6.Has been exported to Europe, South America, Asia, Africa and other regions, and can be viewed in real time

Shine Plywood Veneer Drying has features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. Some of the outstanding faetures include our Biomass Burner,Heat Exchanger and Automatic Feeder Device. The plywood veneer dryer machine has the minimum electrical and fuel consumption, maximum production, quality than the best and energy efficient as well. The veneer is fed into the dryer and moved through the dryers by running rollers and at the same time the hot air blows the surface and back of the veneer to achieve the drying effect. We can different type veneer dryers machine to meet users special capacity requirements.

Working principle of Plywood Veneer Drying

The veneer dryer is driven by the chain to run the upper and lower rollers, relying on the upper roller to press the veneer to run. Biomass combustion furnace is used to burn wood chips, waste wood and other materials at high temperature. Materials boil and fluidize in the burner to provide heat energy to the veneer dryer.For process the surface veneer and long core veneer, this veneer dryer can avoid the break of the veneer, then can raise the veneer utilization ratio and production output.

Biomass Burner

The biomass burner is Shine patented product. It can burn all kinds of waste wood directly to reduce the drying cost mostly. Compared to steam type or heat conduction oil type veneer dryer, the drying cost is reduced greatly.

Product Parameters of Veneer Drying

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

The installation

Customer Case

The Factory

Packaging & Shipping