Low Cost Veneer Dryer

The 4 deck veneer dryer uses biomass burner heating to provide heat source, It can burn all kinds of waste wood directly to reduce the drying cost mostly. heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. and the dried veneer is flat and has good effect.

Product Description of Veneer Dryer

Shine 4 deck veneer dryer is our newly developed product to meet high capacity requirements of customers, which has the salient features of higher drying capacity. The rollers use φ102 steel special shaft tube. The bearings of 4 deck veneer dryer are featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance which no need injecting oil and easy maintenance in the daily operation.A unique heat exchange structure makes the equipment run efficiently and greatly improves drying output.

Biomass burner is our patented product, which can burn waste wood (rotary cutting veneer, waste bark, and waste veneer) directly, heat air, and deliver to the dryer directly without heat loss. The fuel cost is much lower than thermal oil, steam gas, electricity, and others. The composite cost is only about $10/m³.Our biomass burner can pass the inspection and acceptance of the environmental protection department.

4 Deck Biomass Veneer Dryer in Myanmar

Biomass burner

Advantages of 4Deck Veneer Dryer

1. Shine biomass veneer dryer has the features of high veneer drying productivity,energy efficiency, lowest drying veneer cost and perfect veneer drying effect.The composite running cost is only about $12/cubic meter,which can improve customers' profit space greatly.

2. Customized working width of the 4deck veneer dryer is 4500m,the main body of the core veneer roller dryer is 40 meters length,divided into 36 meters drying chamber,and veneer cooling chamber 4 meters length.

3. The working layers, working width, and heating length of the Shine veneer dryers are available to be customized as per customers' specical requirements.

4. Shine Machinery is the only one factory in China who can make not only veneer dryer but also the heat source of the roller dryer, namely, biomass burner.

5. Unlike the steam boiler or thermal oil heater which are traditional heat source installed for the dryer, the biomass burner is the exclusive patented product that can completely burn crushed wood chips, and tree barks directly as the fuel, solving the waste accumulation problem in the veneer and plywood making factories. At the same time, the fuel cost is reduced mostly.

6. Professional R&D team can design different veneer dryer models according to customers' special requirements.

7. Perfect after-sale service system can ease the mind of customer after installation as we supply 24 online services and remote operation. Regular follow up service for old customers, and sufficient spare parts supply in time.

Running Video of the Biomass Veneer Dryer

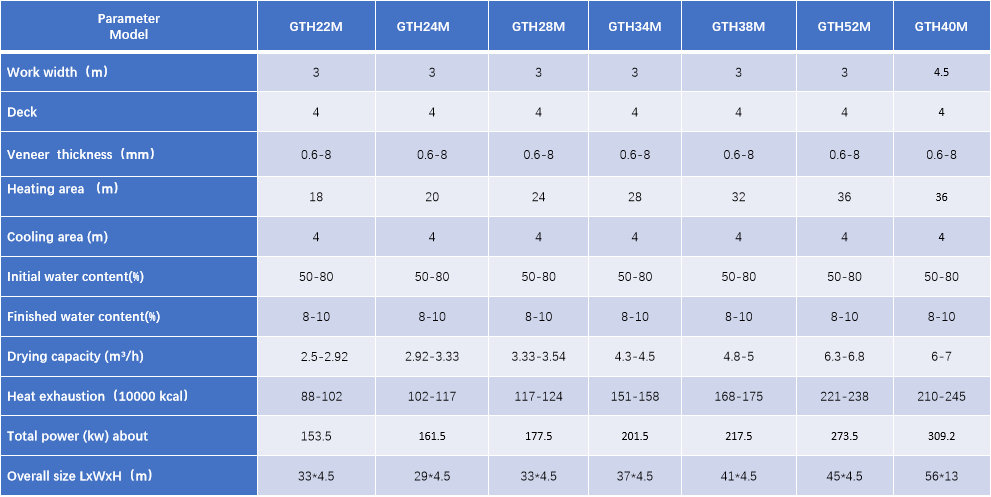

Technical Specifications of 4 Deck Veneer Dryer

Certificates of Biomass Veneer Dryer

Roller Dryer Worksites

Factory

We are very welcome to visit the site and our factory