Customizable Veneer Drying Solutions

Shine veneer dryer machine has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

Type: Roller Veneer Dryer Machine

Working Width: 3m

Veneer thickness: 0.8-8mm

Heating Area Length: 56m

Drying capacity (m³/day) : 80-90

Veneer Water Moisture: Fresh veneer to about 0-15%

Cost: 6-12$/m3 (Labor+Fuel+Electricity)

Heat Source: Biomass Burner (Other options available)

veneer dryer machine is the key machine in making high quality veneer and plywood process. The veneer after drying by the shine veneer dryer is smooth and the moisture content is uniform, the high-temperature rollers have direct contact with the wet veneer for heat transfer, the heat efficiency is high, the heat loss is small, and the heat loss is reduced. The selling price for veneer dried by roller Veneer dryer is higher than natural air drying. The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve an ideal drying effect.

Biomass Burner:

It can directly burn all kinds of waste wood (wood chips, branches, corncob, waste wood, etc.), and the wet wood with a humidity of more than 40% can also be fully burned,The generated exhaust gas meets environmental protection requirements. And fully burned, the overall water circulation cooling system can ensure the service life of the burner, and there is no problem in long-term operation. There are different sized burners according to the size of the dryer equipment.

Shine veneer dryer machine is smooth and the moisture content is uniform, the high-temperature rollers have direct contact with the wet veneer for heat transfer, the heat efficiency is high, the heat loss is small, and the heat loss is reduced. The selling price for veneer dried by roller veneer dryer is higher than natural air drying. The roller veneer drying machine adopts frequency conversion to adjust feed speed according to your veneer thickness and moisture content to achieve an ideal drying effect.

Product Parameters of Veneer Drying Solutions

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

The installation

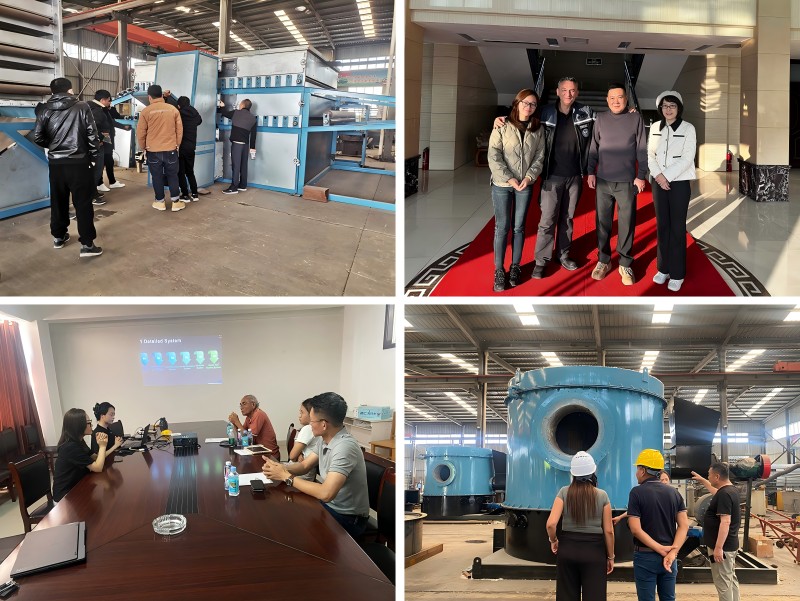

Exhibition and Customer Visiting

The Factory

Packaging & Shipping