Wood Veneer Dryer Machine

Wood Veneer Dryer Machine can supply high efficiency with lowest drying cost. Our veneer drying machine has advantages of high productivity,energy efficiency and perfect drying effect. 4deck veneer dryer is a new technology,which equipped with automatic feeder device can feed the veneer to dryer and save labor cost mostly. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness. Less maintenance is required for Shine veneer dryer machine and no veneer jamming leading to less downtime. Shine biomass veneer dryers machine can reach user's special requirements and achieve ideal drying effect mostly.

Wood Veneer Dryer Machine

Shine Wood Veneer Dryer Machine has the higher drying capacity and higher energy efficiency as well as the less drying cost. The 4 deck roller veneer drying machine is equipped with automatic feeding machine which ensure the high feeding rate for the wood veneer dryers. We have a professional R&D team that can design different models according to customer’s special requirement. Shine Veneer Dryer is the most economical dryer available because it consumes much lower power as compare to the any other brand.

The wood veneer dryer machine can control the drying process by adjusting parameters such as temperature, humidity and ventilation according to different wood types and requirements. This makes the drying quality more controllable and can meet the needs of different users. The veneer dryer can effectively control the temperature and humidity of the wood during the drying process to avoid problems such as cracking, deformation and quality degradation of the wood. This ensures the stability and quality of the wood.

Our veneer dryers are suitable for all sizes and needs. Whether you are a self-employed woodworker or a large production operation, we have customization options to suit you. Diversified capacities and specifications to meet the unique needs of your different projects.

Product Parameter of Wood veneer dryer machine

Model No | GTH45-34 |

Working Width | 4.5m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 30m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 150-160 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 11KW(15pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 257.5KW |

Actual electricity consumption | About 180kwh per hour |

Overall Dimension(L*W*H) | 46m×12m×3.5m |

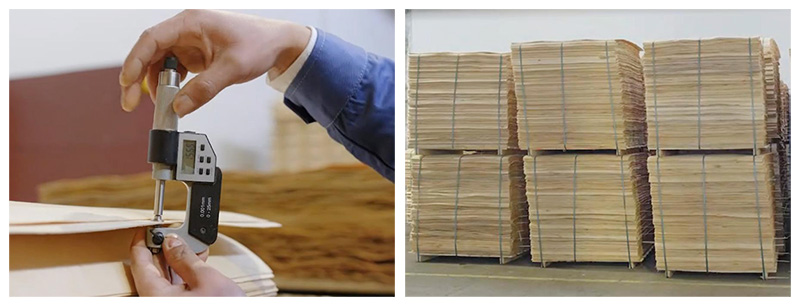

Certification

Customer Visiting

Factory

Packaging & Shipping