Wood Veneer Dryers

Shine wood veneer dryers It has been exported to more than 100 countries and regions, and has agents in more than 50 different countries. Users can visit the project case scene nearby. Compared with traditional dryers, 35-40% reduction in operating costs in the later stage. High cost performance 、low failure rate and large veneer drying output.

The working width and working length of the wood veneer dryers can be customized according to the specific drying capacity requirement needed by the different customers. Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, and the hot air in the heat exchanger can be uniformly emitted to the veneer. The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

The Automatic Veneer Feeder, splitting system and Automatic Veneer Collection System are the first Automatic Veneer Feeder and Collection Systems for veneer dryers in China. Only 1-2 people are on duty at both ends of the dryer, which solves the problem of manual board feeding personnel. Problems of large quantity and high labor intensity. From board feeding to board collection, full automation is achieved. The dryer is not easy to block boards and is highly efficient and energy-saving. The company has been in the drying industry for a long time, has rich experience, and has guaranteed after-sales service.

Product Parameter of Wood Veneer Dryers

Model No | GTH30-36 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 32m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 110 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 8KW(16pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 212.5KW |

Actual electricity consumption | About 149kwh per hour |

Overall Dimension(L*W*H) | 47m×11m×3.5m |

Certification

Customer Case

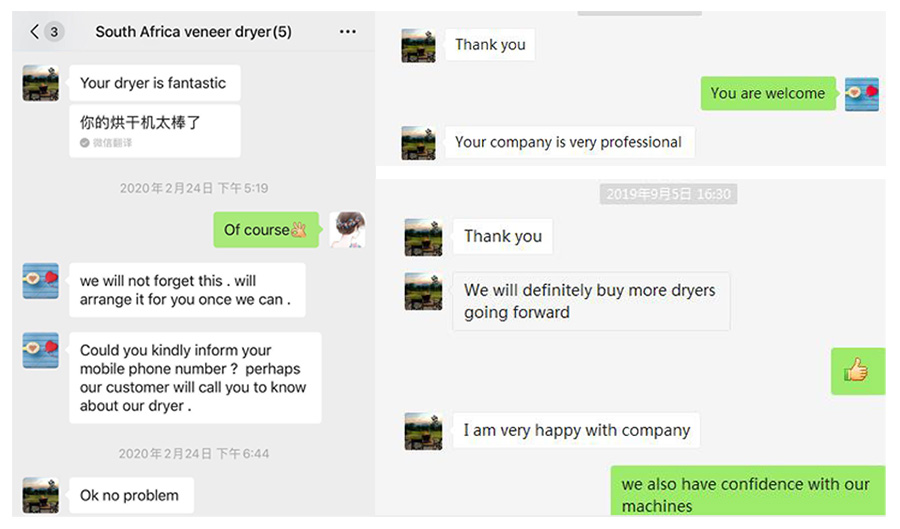

Customer Feedback

Factory

Packaging & Shipping