china roller veneer dryer machine

1.Professional factory production

2.Customizable (customized one-stop service)

3.The dryer output is 2-3 times that of the original traditional dryer

4.Stable equipment and low failure rate

5.Convenient installation (installation can be completed in 25-30 days)

6.Imported accessories, using thicker high-quality steel

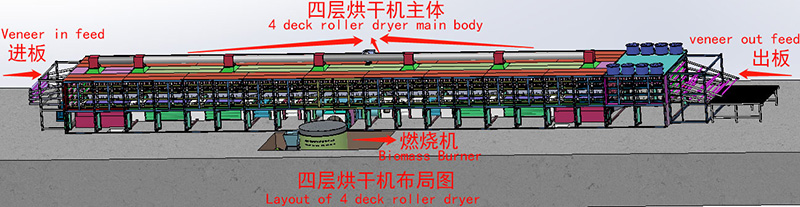

When it comes to delivering high-performance drying solutions, our veneer dryers are trusted by woodworking businesses around the world. Recently, we had the pleasure of designing and delivering a custom-built 4 deck roller veneer dryer to one of our long-standing clients in South American.

One of the most impressive outcomes for our South American client was the significant energy savings. Our veneer dryers use innovative energy-saving systems, reducing power consumption by over 35%, helping them control operating costs while still hitting high production targets. This veneer dryer is your key to more efficient production, higher quality products, and long-term success.

Advantages of Veneer Dryer Machine

1. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

2. The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

3. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

4. After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

5. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

6. We have a professional R&D team which can design different models according to customer’s special requirement.

7. The perfect after-sale service team can supply 24 hours online service.

Product Parameters of Veneer Dryer Machine

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Exhibition and Customer Visiting

The Factory

Packaging & Shipping