Automated Conveyor Veneer Dryer

1.Customizable (customized one-stop service)

2. Professional factory production

3.Stable equipment and low failure rate

4. Low comprehensive operating cost, the cost of one cubic board is 6-12$/m3

5. Users can visit the case site nearby

6. The veneer is flat and wrinkle-free after drying

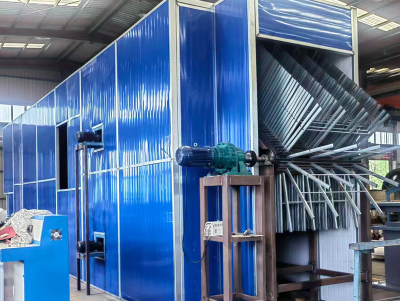

4 Deck Roller Veneer Dryer Machine has low power consumption, so the veneer drying machine can be used in small and medium plywood plants to dry the core veneer. The 4 deck veneer roller dryers allow automatic feeder devices, which can save labor costs greatly. With a biomass burner, all kinds of waste wood such as tree bark, and the waste veneer can be burned as fuel directly, even if the waste wood is wet. The temperature inside our Roller Veneer Dryer machine is high enough to reduce moisture content. The 4 deck biomass veneer drying machine can ensure a perfect drying effect and reduce drying costs mostly.

Equipped with biomass burner, which can ensure perfect drying effect and reduce drying cost mostly. The veneer after drying has a uniform moisture content, is flat, has no buckle or end waviness, good surface condition before gluing. The rollers use φ102 steel pipe. The bearings of the 4 deck veneer dryer are featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance, which no need inject oil and easy maintenance in the daily operation.

Advantages of Roller Veneer Dryer Machine

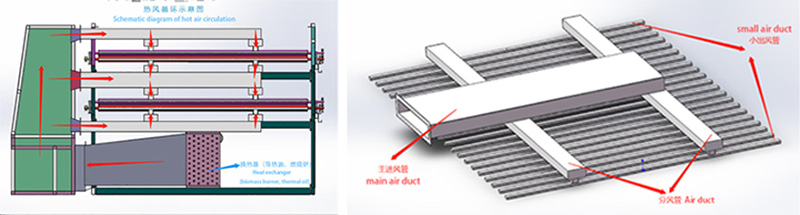

1.The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste. It has obtained the national invention patent.

2.The control cabinet has automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

3.The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180 ℃, which shortens the drying time and increases the output.

4.After drying, the veneer is smooth, with no cracks, wrinkles, or end ripples.

Product Parameters of Conveyor Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | 4 deck veneer dryer | |||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

The installation

Customer Case

The Factory

Packaging & Shipping