Roller Veneer Dryer Machine

The roller veneer dryer machine adopts frequency conversion speed regulation, which can adjust the feed speed according to the veneer thickness and moisture content to achieve the ideal drying effect. Higher thickness of roller walls ensuring longer life without getting distorted and smoother dried veneer. Veneer dryer machine is composed of transmission room, drying room, cooling room and other parts. This equipment highlights less investment and cost-effective advantages. We can design veneer dryer according to the needs of customers.

Roller Veneer Dryer Machine

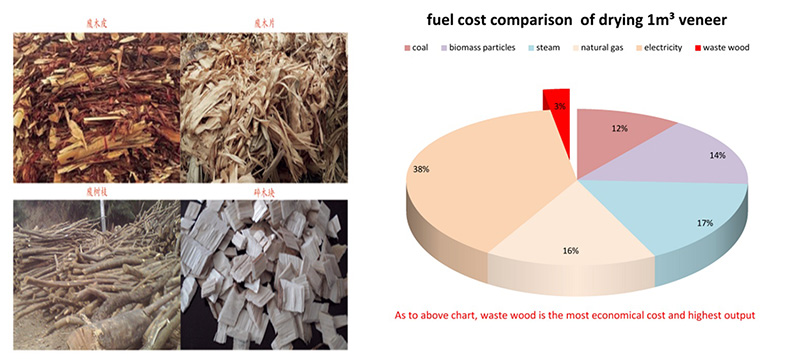

roller Veneer Dryer Machine is used for drying sliced or peeled veneer in the plywood production line.Shine veneer drying machine consists of inlet, drying area, cooling area, outlet. Veneer Dryer size is customized according to the production capacity, process and space.Shine wood veneer dryer can achieve high productivity with lowest investment.Biomass burner as a environmental boiler,which can burn waste wood directly to reduce fuel cost mostly.The composite cost of face veneer dryer is about $6-12/cubic meters.We also can design different veneer dryers machine to meet users' needs.

Main Features of Shine roller veneer dryer

2. The temperature in the burner is 40-60 ℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-200 ℃, which shortens the drying time and increases the output.

3. The well-developed heat exchange system fully improves the energy utilization rate and saves unnecessary energy waste.

4. The control cabinet has an automatic temperature control and speed regulation system, which can accurately control the final moisture content. Simple operation and low failure rate.

5. After drying, the veneer is smooth, no cracks , wrinkles or end ripples.

6. Shrinkage and hardening are kept to a minimum and veneer collapse and honeycomb structure are avoided.

7. We have a professional R&D team which can design different models according to customer’s special requirement.

8. The perfect after-sale service team can supply 24 hours online service.

Product Parameters of Roller Veneer Dryer Machine

Model No | GTH30-24 |

Working Width | 3m |

Deck | 1 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 20m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200 °C adjustable. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | About 15-18m³/day |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(5pc) |

Traction motor | Power: 5.5KW,frequency control(1pc) |

Cold air blower | Power:5.5KW(1pc) |

Air intake fan | Power: 11KW(1pc) |

2 ton biomass burner | Power: 15KW |

Total power | 64.5KW |

Actual electricity consumption | About 46kwh per hour |

Space covered about | 28m× 9m×2m |

Customer Case

Customer Visiting

The Factory

Packaging & Shipping