COMPANY PROFILE

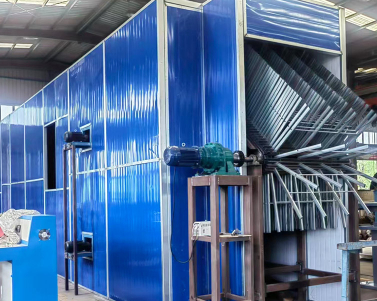

A large-scale enterprise specializing in R&D and production of core veneer dryer and face veneer dryer.

We have a professional R&D team and experienced after-sale service team to supply best drying solution for different customers.

Established in 1999, Shandong Shine Machinery Co., Ltd is a large-scale enterprise specializing in R&D and production of veneer production line、core veneer dryer and face veneer dryer. We have 50 persons for the design, R&D Team and more than 100 workers in the workshop. We are honored to be recognized as the vice president unit of Shandong Timber and Wood Products Distribution Association. It has 10 standardized workshops, covering an area of 70000 square meter, and has a building area of 12,000 square meters. It has 150 sets of various equipment and has complete machining, heat treatment, punching, welding, and assembly and painting totaling six production lines. We have a professional R&D team and experienced after-sale service team to supply best drying solution for different customers. Shine roller veneer drying machines have been exported to more than 20 countries such as Latvia, Indonesia, Vietnam, Thailand, Laos, Malaysia, Cambodia, Myanmar, Brazil, Bolivia, South Africa, South America, Ethiopia, The Republic of Congo and etc.

1999

established in

180people

employee

40people

After sales team

220tower

Number of foreign equipment

56 m 2 Deck Veneer Dryer in Thailand

Shine Patented Biomass Burner

directly use crushed wood waste as fuel, comprehensive drying cost for one cbm is about$10 lower than thermal oil or steam boiler.

Read more

38m 4 Deck Veneer Dryer in Myanmar Yangon

Automatic Speed And Temperature System

The transmission speed and temperature can be automatically adjusted according to the thickness and moisture content of different veneers to achieve the ideal drying effect, and the final moisture content can be accurately controlled.

Read moreGood Veneer Drying Quality

The heat exchange is carried out step by step, and the hot air in the heat exchanger can be evenly distributed to the veneer. The veneer after drying has a uniform moisture content, is flat, has no wrinkles or end ripples, has no cracks, and has a good surface bonding condition.

Read more

4 Deck Veneer Dryer in Latvia

Professinal Technical Support Service

We have a professional R&D team that can design different models according to customers' special requirements; a complete after-sales service system can provide 24-hour online service, remote operation, regular visits to customers and sufficient supply of spare parts, etc.

Read more

New 4 deck Veneer Dryer Installed in Romania

certifcate

certifcate

certifcate

certifcate

certifcate

certifcate

24 m 1 deck roller veneer dryer with 2 ton biomass burner ordered by Brazilian customers,Veneer

Read more

After purchasing one of our veneer dryers, our Zimbabwean customers feel that our equipment is very

Read more

On March 11,2019,a Thai customer took a flight to visit the completion of our veneer dryer

Read more

2019.12.03 The Latvian customer's 4 deck veneer dryer is in production,using chrome plating

Read more

A Landmark Visit: Russian Business Delegation Praises Advanced Veneer Drying Technology at

Read more

Our veneer dryer purchased by Myanmar customers last year is being delivered,and customers will receive it soon.We have a professional R&D team that can design different models according to customer’s special requirement.Perfect after-sale service system can supply 24h online service,remote

2022-08-10

Read more

Shine Machinery Co., Ltd. held a two-day centralized training for company members on August 12, 2022. The training contents include product performance sorting of Shine biomass veneer dryer, business speech training, after-sales service process, etc. Each business manager presents in the form of

2022-09-23

Read more

The three-day exhibition of wood industry and woodworking machinery and equipment was successfully concluded. At the exhibition, we showed our company's advanced drying equipment with many enterprise operators in the wood processing industry, which was recognized by the majority of merchants. At

2022-09-23

Read more