News Center

This 2 deck 56-meter-wide 3.75-meter-wide roller veneer dryer was purchased by our Thai customer. It has been produced and ready for shipment. It is equipped with our biomass burner to save fuel costs. We will be sent to you when it is installed. Engineers go to the customer's factory to guide the…

2024/01/23 09:42

Veneer dryers generally need to make preparations before the official test run to ensure that the test run can proceed normally. The preparation work required before the test run mainly includes the following points:Warming furnace: The high-temperature-resistant material poured into the burner is…

2024/01/18 09:20

With the gradual cancellation of natural drying, many bosses are inspecting veneer dryers. If you want to see the case site, you can contact us at any time. Many customer case sites in South Africa, Myanmar, Romania, Guangdong, Yunnan, etc. are waiting for you to see!

2024/01/16 10:14

Recently, customers have been coming to our factory to visit and inspect the veneer dryer, or go to the case site to see it in action. After the inspection, the customer was very satisfied. Some of the questions raised by the technicians were answered in detail. If you want to inspect the equipment…

2024/01/11 09:54

Shine economical vertical dryer is a type of horizontal dryer and a drying equipment based on the principle of two-way conveying. The material is manually put into the upper grid plate of the dryer inlet from the head of the dryer. The material is evenly distributed on the grid plate and runs…

2024/01/09 09:53

The 2 deck roller veneer dryer is equipped with a 6-ton biomass burner, which produces more than 70 cubic meters per day. It is being installed in Russia.

2023/12/27 09:13

First: the type of wood to be dried, whether poplar, pine, eucalyptus, or rubber wood.Second: The thickness and size of the dried veneer, such as 1.7 or 2.2 thickness, four-piece or three-piece, etc.Third: What is the moisture content requirement and output after drying, how much water needs to be…

2023/12/19 10:43

The veneer dryer purchased by the South African customer has 4 deck of 50 meters and a width of 4.5 meters. It uses an automatic dialing machine, a semi-automatic dividing board machine and a collecting machine. It is equipped with our 15-ton biomass burner and can directly burn waste trees. It not…

2023/12/15 09:32

Since the veneer dryer is a long and large-scale equipment, the correct order and method should be followed when installing the veneer dryer. The correct installation process is as follows:1. Draw the foundation line: correctly draw the cross lines and elevation lines on the foundation mark plate,…

2023/12/13 10:05

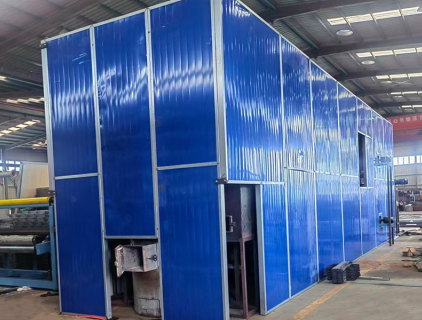

The installation of the 2 deck veneer dryer purchased by another of our customers has been completed! This wood veneer dryer is equipped with our biomass burner, which saves fuel costs and uses new technology to save energy and electricity. Our engineers will go to the customer's factory to guide…

2023/12/07 10:20

The second set of 4 deck veneer dryers ordered by our Latvian customer has been completed and is ready to be shipped. The customer was very satisfied with the first set after purchasing the first set. They expanded production this year and approached us to order another one. Thank you very much for…

2023/12/05 10:23

The recent Russian Woodworking Exhibition is in progress. Our company's Russian agent participated in this exhibition. Our equipment has the advantages of high efficiency, energy saving and low drying cost. With our biomass burner, it can save fuel for you. It can directly burn various Plant waste…

2023/11/30 11:17