Veneer Dryer Machine Heat Exchanging System

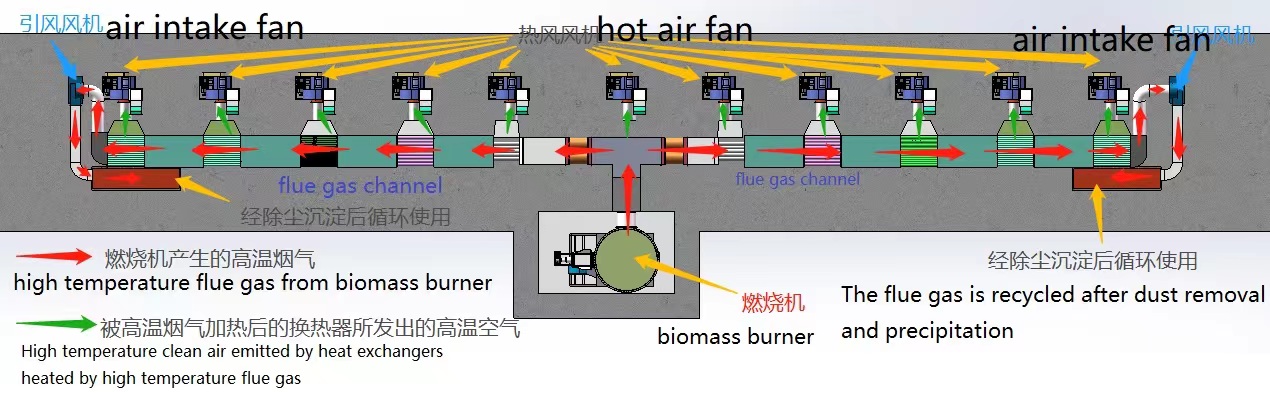

Shine heat exchanger adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, Large heat exchange area and high heat exchange efficiency. and the hot air in the heat exchanger can be uniformly emitted to the veneer.

Product Description

Shine Veneer Dryer Machine Heat Exchanging System adopts step by step heat transfer, and the specifications of each section of the heat exchanger are different, Large heat exchange area and high heat exchange efficiency. and the hot air in the heat exchanger can be uniformly emitted to the veneer. The veneer after drying has uniform moisture content, flat, no buckle or end waviness; free of splits and the surface is in good condition for gluing.

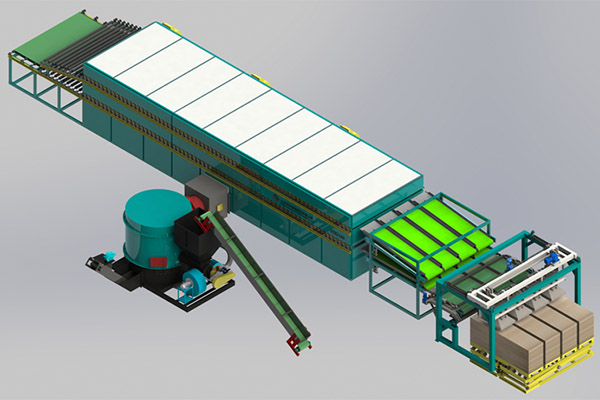

Veneer Dryer in Zimbabwe Customer Factory

For traditional veneer dryer, the position of the hot air fan is on the top of the veneer dryer.

The position of the hot air fan is on the side of the Shine roller veneer dryer. The advantages are as follows:

On the one hand, it can decrease the height of the equipment.

On the other hand, the heat is more concentrated and the heat loss is less. The motor of the hot air fan is on the side of the veneer dryer where temperature is not so high, so the motors are in a suitable working condition which prolongs its working life.

Last but not least, it is very convenient for daily maintenance of the equipment.

Other Parts of Veneer Dryer