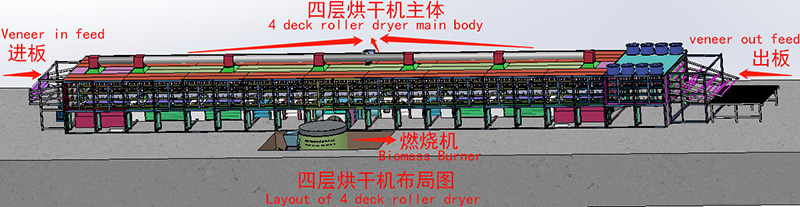

High Efficiency 4 deck Veneer Dryer Line

The veneer dryer minimizes energy consumption and saves costs for your production process. Through precise temperature and humidity control, the effect of the veneer during the drying process is ensured. The automated control system improves production efficiency. SHINE provides you with customized veneer drying solutions. If you want to know more details about the machine (performance, detailed parameters, videos, etc.), please contact us(WhatsApp: +8615806625431)

High Efficiency 4 deck Veneer Dryer Line

The 4 deck veneer dryer is easy to operate and has a low failure rate. Compared with traditional dryers, it has a good drying effect. The dried boards are flat and wrinkle-free, and the shrinkage rate is controlled at a very low level.

It has a high degree of automation and diverse heat sources. The heat exchanger adopts step-by-step heat exchange. The specifications of the heat exchanger in each section are different, and the hot air in the heat exchanger can be evenly distributed to the veneer.

Fully automatic control and frequency conversion control system

Adopting fully automatic control and frequency conversion control system, the transmission speed and temperature can be automatically adjusted according to the thickness and moisture content of different veneers to achieve the ideal drying effect, and the final moisture content can be accurately controlled. It avoids the phenomenon that a large number of veneers are over-dried or the drying does not meet the process requirements.

Product Parameters of Veneer Dryer Line

Model No | GTH30-36 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 32m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 110 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(32pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 15KW(2pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 212.5KW |

Actual electricity consumption | About 149kwh per hour |

Exhibition and Customer Visiting

The Factory

Packaging & Shipping

Our Services

Pre-sale services:

1) Provide the free consultation of all veneer dryer

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging(Technical phone:+8615806625431)Door to door service is possible.