Eucalyptus Veneer Dryer

1.Customizable (customized one-stop service)

2.Professional factory production

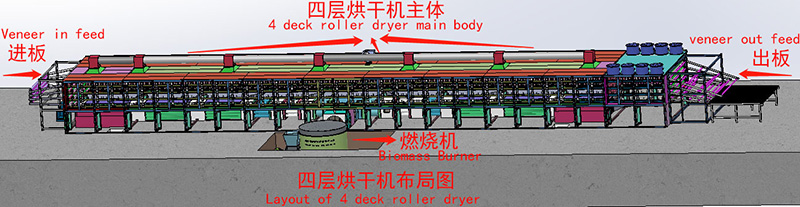

3.The dryer output is 2-3 times that of the original traditional dryer

4.Diverse heat source options

5.The veneer is flat and wrinkle-free after drying

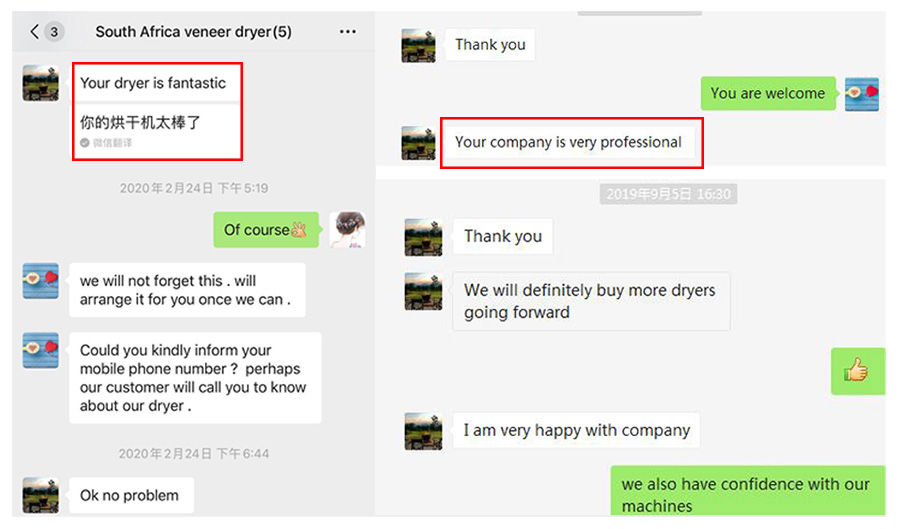

6.Has been exported to Europe, South America, Asia, Africa and other regions, and can be viewed in real time

Our wood veneer dryer Machine is an advanced drying solution designed for high efficiency and productivity. Engineered with state-of-the-art automation technology, this machine ensures consistent drying quality, reducing manual intervention and operational costs. Ideal for plywood manufacturing, furniture production, and other wood-based industries, our Veneer Dryer enhances your production capabilities while significantly cutting down on energy consumption.

Advantages of Veneer Dryer

Advanced Automation: Equipped with intelligent control systems, our wood veneer dryer automatically adjusts temperature and humidity settings to optimize the drying process. This automation minimizes human error, ensures uniform drying, and reduces the need for constant monitoring.

High Productivity: The machine is designed to handle large volumes of veneer with ease, maintaining a consistent production flow. Its high-capacity drying chambers and rapid processing capabilities allow for increased output, meeting the demands of large-scale production environments.

Uniform Drying Quality: With precise control over drying parameters, the machine ensures that each sheet of veneer is dried evenly, preventing warping, cracking, or other defects. This uniformity is critical for producing high-quality end products.

Durable Construction: Built with high-grade materials, the dryer is designed to withstand the rigors of continuous operation in industrial settings. Its robust construction ensures longevity and low maintenance requirements.

Safety Features: The machine includes multiple safety systems, such as over-temperature protection and emergency shut-off mechanisms, to safeguard both the equipment and operators.

Applications

Plywood Manufacturing: Essential for drying veneers used in plywood production, ensuring the right moisture content for further processing.

Furniture Production: Used in preparing veneer for high-quality furniture, ensuring smooth finishes and durability.

Wood-based Panels: Applicable in the production of various wood-based panels, including MDF, HDF, and particleboard.

Architectural Woodwork: Ideal for drying veneers used in decorative and structural woodwork, ensuring they are ready for lamination and installation.

Product Parameters of Veneer Dryer

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Customer Case

The customer evaluation

Our Services

Pre-sale services:

1) Provide the free consultation of all plywood production line

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operator.

After sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging(Technical phone:+8615806625431)Door to door service is possible.

The Factory

The installation

Packaging & Shipping