Biomass Veneer Dryer

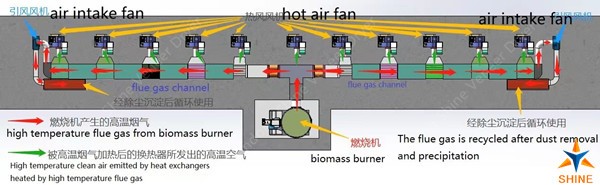

Biomass burner is the exclusive patent of Shine Machinery Co., td. Biomass burners can use local materials to directly burn waste wood cut by rotary cutters.We recommend using 2T biomass burner for single deck biomass veneer dryer,which can generate 1.2 million calories per hour.

Product Description of Biomass veneer dryer

Biomass Veneer Dryer not only solves the key problem of high energy consumption of veneer drying equipment, but also solves the serious problem of waste accumulation in wood processing plants. The water circulation system specially designed by Shine biomass burner can cool down, remove dust and prolong the service life of the machine.

The waste wood is fed spirally, and there are many hoods at the bottom of the furnace, which can maintain ventilation and make the fuel burn fully in the furnace, so as to produce a stable high temperature. The waste slag is discharged from the bottom of the combustion furnace and finally output through the slag remover. And the drying cost is greatly reduced -- no high-cost fuels such as natural gas, coal or oil are required. The temperature in the drying oven is 140-180 ℃, 40-60 ℃ higher than that of steam and heat transfer oil, which greatly shortens the total drying time and ensures the output.

Biomass veneer dryer in Brazil

Biomass Veneer Dryer

Biomass Veneer Dryer Video of Customer Factory

Product Parameter of Biomass Veneer Dryer

The fuel cost of using biomass burners is lower than other fuels since we use waste wood. Here is the comparation.

Project Case of Biomass Veneer Dryer

Exhibitions we attend

We have attend various exhibitions and we welcome you yo visit our Company.

Our Certificate

Product Transportation

We can help you to find a variety of transport options. The main part can be shipped in containers, and the accessories can be shipped by air.

Our Services

1.According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

2.Welcome to visit our factory

3.Inspect the machine before leaving the factory.

4.Oversea install and debug the equipment

5.Train the first-line operator.

6.Provide the VIDEO with Install and debug the equipment

7.Provide technical exchanging

8.Door to door service is possible