50M 4 Deck Veneer Dryer Machine

High Automation: auto feeder and veneer grading line installed for 50M 4 Deck Veneer Dryer Machine

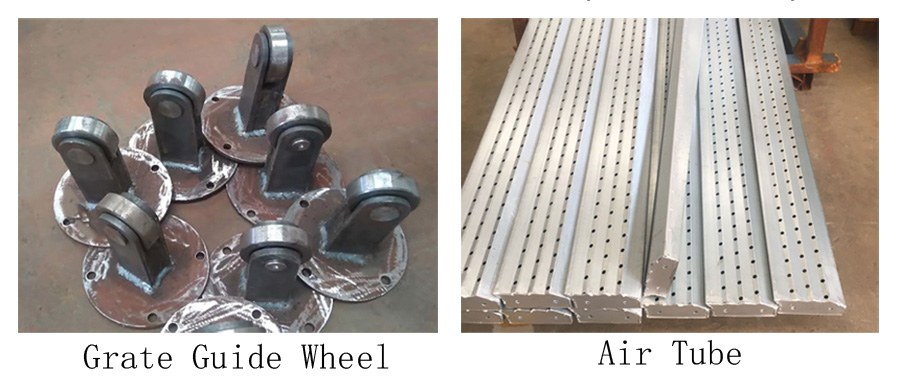

The Nozzle or Jet box(air tubes) in saw tooth thread design prevents veneer jamming in the drying process.

The roller distance is 330mm and the wall thickness of the roller is 2.5mm.

Energy Efficiency: The hot air fans are 4kw fans with a large air volume, which ensures the sufficient air volume required by the dryer but also reduces the total machine power.

Product Description of 50M 4 Deck Veneer Dryer Machine

The 50M 4 deck veneer dryer machine with Veneer Grading Machine has the veneer drying capacity of 160m3 per day. Veneer drying is part of a complete plywood and LVL production process. The standard working width of the 50M 4 deck veneer dryer machine is 3000mm and the customized width is also available in line with the specific requirements from customers. One of the main things to veneer drying machine is that the veneer sheet should be dry enough for gluing into plywood sheets.

Shine veneer dryer's patented moisture exhaust system is specially designed for users in cold northern regions. It can be installed separately on any of our dryer models. The system is installed on the top of the Shine's veneer dryer to quickly and discharge the moisture inside the dryer to the outside of the workshop, avoiding the pre-condensation of steam caused by the temperature difference between the inside and outside of the dryer, and keeping the inside of the dryer dry and pressure balanced.

50M 4 Deck Veneer Dryer Machine in Latvia

Advantages of 50M 4 Deck Veneer Dryer Machine

1. The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

2. The veneer after drying is free of splits and the surface is in good condition for gluing.

3. Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

4. Shine veneer dryer is equipped with automatic control system with merits of saving labor cost, easy operation and low failure rate. Main electrical components are internationally famous brands.

5. Shine veneer dryer adopts frequency conversion, which can adjust the transmission speed and temperature automatically according to different veneer thickness and moisture content to achieve an ideal drying effect.

6. Less maintenance is required for Shine veneer dryer and no veneer jamming/clogging leading to lesser downtime.

7. Total power of the 4deck veneer dryer is the least to dry the large capacity veneer. Energy efficiency is considerably high.

Video of the 50M 4 Deck Veneer Dryer Machine

Technical Parameters of the 50M 4 Deck Veneer Dryer Machine

Model No | GTH30-50 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 46m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 6.5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(46pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

10ton biomass burner | Power: 16.5KW |

Total power | 276.5KW |

Actual electricity consumption | About 190kwh per hour |

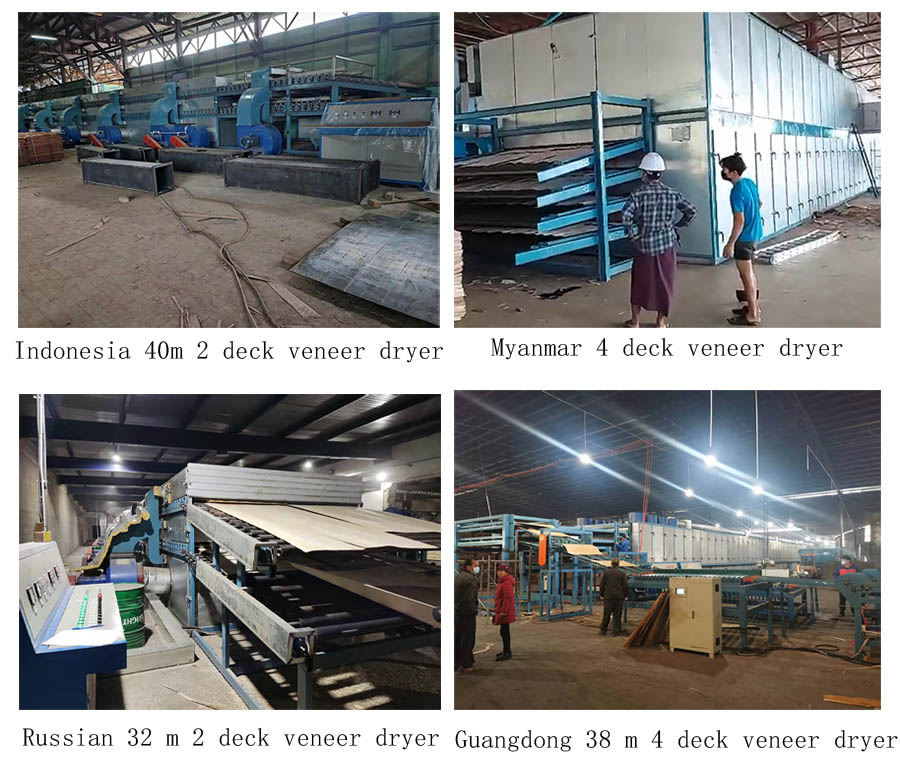

Roller Dryer Sites

Exhibitions