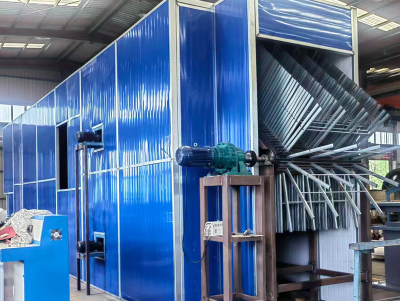

Roller Plywood Veneer Dryer machine

1.Customizable (customized one-stop service)

2. Professional factory production

3.The roller uses a φ89mm special shaft tube, which is corrosion-resistant and rust-proof

4.The main electrical components are all well-known domestic and foreign brands

5.Energy saving and power saving, using axial flow fans, the power of the whole machine is reduced by 38%

The roller veneer dryer adopts a fully automatic control system and a variable frequency control system, which can intelligently adjust the transmission speed and temperature according to the thickness and moisture content of different veneers, thereby ensuring that each veneer can achieve the ideal drying effect. Compared with traditional drying equipment, the power of this machine is reduced by 38%, significantly improving energy utilization and significantly reducing operating costs.

The heat exchange system of the veneer dryer adopts a step-by-step heat exchange design. The specifications of each heat exchanger are different, so that the hot air can be transferred to the surface of the veneer more evenly, ensuring full utilization of heat and avoiding quality problems caused by local overheating of the veneer. The automatic loading and receiving system makes the operation of the equipment simpler and more efficient, reduces manual intervention, and improves production efficiency and automation. At the same time, we also provide customized services. According to the specific needs of customers, we can tailor a suitable drying solution. Whether it is the thickness of the veneer, moisture content or production scale, it can be accurately matched to make production more efficient.

Product Parameters of Plywood Veneer Dryer machine

Wood species | Veneer Drying capacity (m³/h) | Veneer water moisture | Veneer thickness and size | |||

1 deck veneer dryer | ||||||

Eucalyptus | 0.5-2 | 1-3.3 | 2-9.0 | 15-17 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Birch | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Rubberwood | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 60%) to about 0% | 0.8-8mm |

Poplar | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 50%) to about 0-10% | 0.8-8mm |

Beech | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Pine | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

Other | 0.6-2.2 | 1.2-3.8 | 2.3-10 | 15-18 | Fresh Veneers (above 70%) to about 0-10% | 0.8-8mm |

shine veneer dryer can dry various types of wood. If you want to know more detailed information, please feel free to contact us! | ||||||

Customer Case

The installation

The Factory

Packaging & Shipping