4 Deck Veneer Roller Dryer

Veneer Type: 4 Deck Veneer Roller Dryer.

Veneer Thickness Range: 0.6mm-8mm.

Drying Capacity: around 120m3 per day.

Veneer moisture content: from fresh veneer to 8-10%(customized moisture content available).

Comprehensive veneer drying cost: USD 12/m3 inclusive of labor cost, fuel cost, and electric power.

Roller Material: Q235B, φ102 special shaft tube.

Heat Source: Biomass Burner, 10ton, 6 million KCAL/h.

Fuel: crushed waste wood, tree bark, wood chips.

Product Description of 4 Deck Veneer Roller Dryer

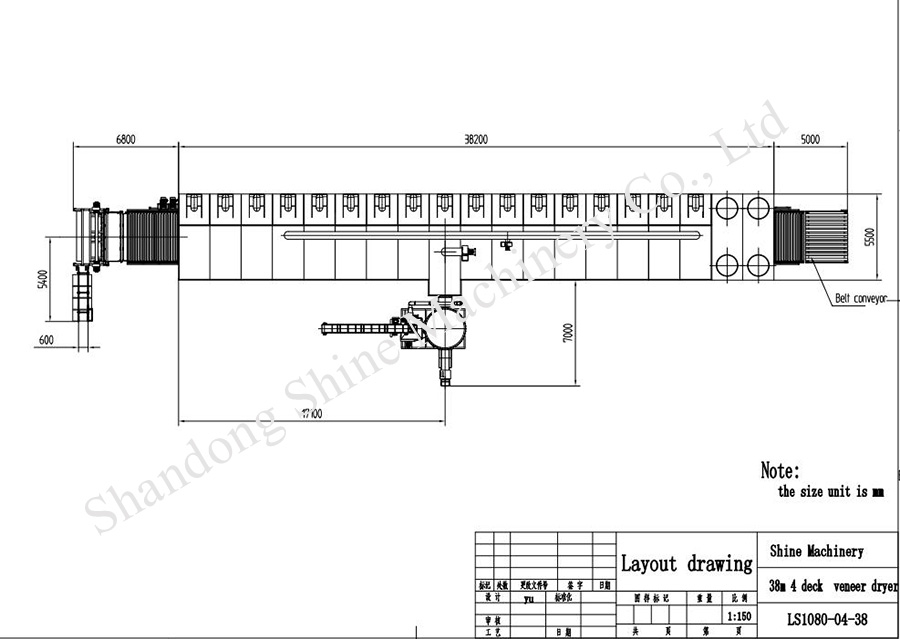

The 4 deck veneer roller dryer has a standard working width of 3000mm.The 38m 4 deck veneer roller dryer is made up of an auto veneer feeder,17 heating sections, one cooling section,a veneer outfeed section, and a 10ton biomass burner(6 million KCAL/h) as the heat source.The total length of the automatic veneer dryer line is 49 meters and the total power of the veneer dryer machine is 236.5KW. The flue gas is blown from the biomass burner into the heat exchangers inside the veneer dryer and is converted into clean hot air which is then impinged into the face and back of the moving veneer. In this way, the excess moisture is removed from the fresh veneer and the dried veneer is flat with uniform moisture content after roller drying.

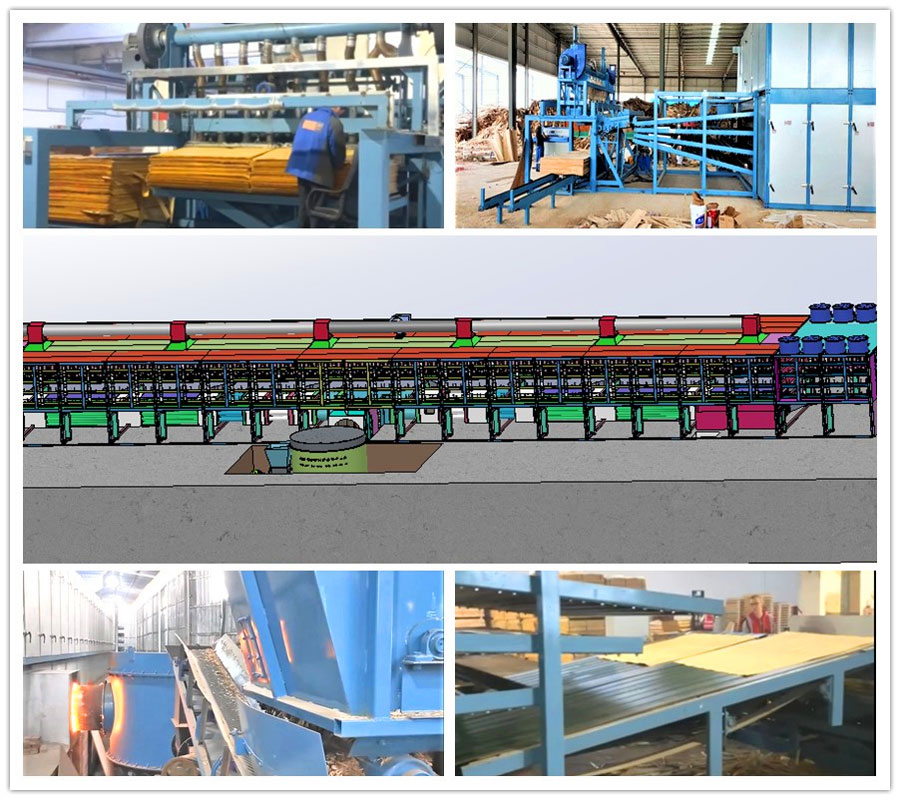

4 Deck Veneer Roller Dryer in Myanmar Customer's Factory

4 deck veneer roller dryer

Advantages of 4 Deck Veneer Roller Dryer

1. 4 deck veneer roller dryer: working width 3.0m, the main body of the core veneer roller dryer is 38 meters long, heating section length 34meters and cooling section 4 meters length.

2. Roller: use φ102 special shaft tube. The bearings of the 4 deck veneer drying machine featured high temperature 500 degree Celsius resistance and low temperature -20 degree Celsius resistance. which no need to inject oil and easy maintenance in the daily operation.

3. Automatic feeder and veneer collection system are installed for the veneer dryer. Only need 1-2 people at both ends of the dryer, which solves the problem of high labor intensity.

4. The biomass burner is the exclusive patented product that can burn crushed wood chips, and tree barks directly as the fuel, solving the waste accumulation problem in the veneer and plywood making factories. At the same time, the fuel cost is reduced mostly.

5. The position of the hot air fan is on the side of the Shine roller veneer dryer. On the one hand, it can decrease the height of the equipment. On the other hand, the heat is more concentrated and the heat loss is less. The motor of the hot air fan is on the side of the veneer dryer where the temperature is not so high, so the motors are in a suitable working condition which prolongs its working life. Last but not least, it is very convenient for daily maintenance of the equipment.

6. Less maintenance is required for Shine veneer dryer and no veneer jamming/clogging leading to lesser downtime.

7. We have a professional R&D team that can design different models according to customer's special requirements.

8. We have a perfect after-sale service system, which can supply 24 online services; remote operation is available on request, regular customer visits, sufficient spare parts supply in time. Fully solve the worries of customers.

Video of the 4 Deck Veneer Roller Dryer

Technical Parameters of the 4 Deck Veneer Roller Dryer

Model No | GTH30-38 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 34m |

Cooling area length | 4m |

Veneer thickness and size | 0.6-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-180°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/h) | 5 |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power: 4KW(34pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(8pc) |

Air intake fan | Power: 11KW(2pc) |

10ton biomass burner | Power: 16.5KW |

Total power | 228.5KW |

Actual electricity consumption | About 160kwh per hour |

Layout Drawing of 4 Deck Veneer Roller Dryer

Certificates of Shine 4 Deck Veneer Roller Dryer

Roller Dryer Shipments

Customer Visits

Customers from all over the world visit

Our Services

1. All kinds of veneer dryer mold can be made by customer's specific requirements.

2. All prices are based on FOB QINGDAO, China

3. Payment by T/T or L/C.

4. All the Parameters above just for reference, as we have been updating all the time.

5. Package: Standard export packing.

6. Warranty: All the machine enjoys one year's warranty except for the electric parts.

7. Any problems of the machine, please feel free to contact us. We will try our best to make it.

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine.

2) According to the clients' special requirements, offering a reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory.

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment.

3) Train the first-line operators.

After-sale services:

1) 24 hours online service.

2) Provide the VIDEO with Install and debug the equipment.

3) Provide technical exchanging.

4) Door to door service is possible.