28m Four Deck Natural Gas Veneer Dryer Shine Veneer Dryer GTH30-28

Cooling zone--------------4000mm

Heating zones--------------------2400 mm

Working width----------------3000mm

Heat carrier---------Natural gas

Productivity--------3.5 m3/hour

Initial humidity---------------80%

Final Moisture---------------≤10%

Max. feed speed-----5-22m/min

Total power-------------141.5KW

Weight--------------------------------100,000 kg

28m Four Deck Natural Gas Veneer Dryer Shine Veneer Dryer GTH30-28/4

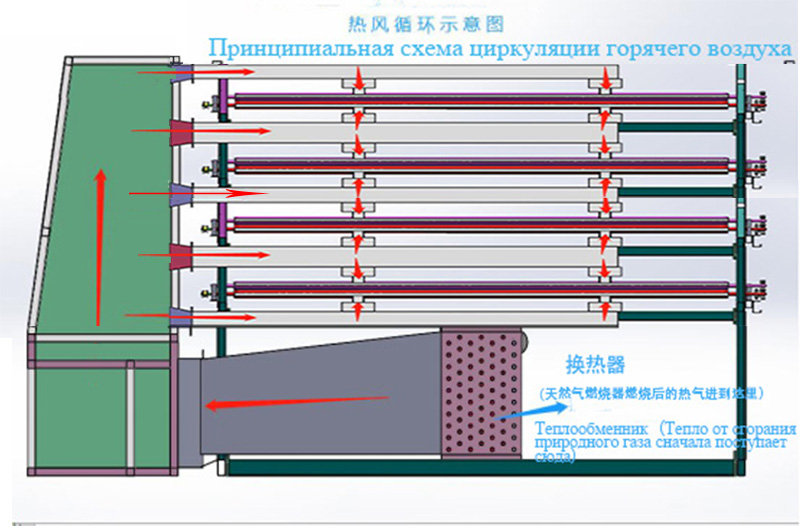

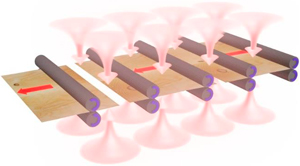

The four-storey roller dryer with flue gas heating is designed for drying veneer with a final moisture content of 0 to 10%. In the veneer dryer, counter-rotating rollers move the veneer in a stream of hot drying agent. In roller dryers, the veneer heats up due to convective heat exchange in the moving drying agent and thermal contact with the rollers.

Specifications:

| Model | GTH30-28/4 |

| Veneer thickness, mm | 0,8 - 8 |

| Initial humidity, % | 80 |

| Final moisture, % | ≤10 |

| Temperature in the dryer, ℃ | 140 - 180 |

| Roller length, mm | 3 200 |

| Working width, mm | 3 000 |

| Number of floors | 4 |

| Heating zones, mm | 24 000 |

| Cooling zone, mm | 4 000 |

| Feed speed, m/min | 5 - 22 |

| Productivity, m3/hour | 3,5 |

| Conveyor power, kW | 22 (5.5 x 4 pcs.) |

| Heating fan power, kW | 96(4 x 2pcs x 12 sections) |

| Cooling fan power, kW | 16(4 x 4pcs) |

| Power-boiler of natural gas, kW | 7.5 |

| Total power, kW | 141,5 |

| Electricity consumption on average per hour, kW | 92 |

| natural gas burner | 2.4 million kcal |

| Gas consumption, m3/hour. | ≈120 |

| Number of personnel, people / cm | 4 |

| Overall dimensions, mm | 39 000*5 000*3 500 |

| Weight, kg | ≈100 000 |

Benefits:

•6 heating sections, 2 cooling sections, 4 floors

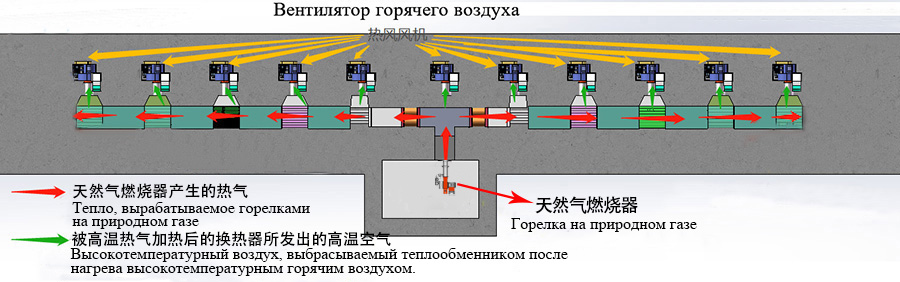

• Use of natural gas as a heat source

•Automatic temperature and drying speed control system

•Combustion and heat exchange system with high efficiency and low drying cost

• The control cabinet has an automatic temperature and speed control system.

• After drying, the veneer becomes smooth, without cracks, wrinkles and ripples at the ends. Doesn't get dark

• Bearings and bushings are resistant to high temperatures and do not require maintenance and repair

• The dryer is equipped with an axial fan with a power of 4 kW * 2 pieces.

• The drying chamber has good thermal insulation from all sides: Galvanized sheet filled with aluminosilicate material has good thermal insulation.

• In 2022, by optimizing the heating and cooling fan motors, the total capacity of our dryer will be reduced by 30-40%, greatly reducing drying costs.

• The system of thermal insulation and moisture removal, which we have developed for cold areas, extend the life of the equipment.

•Our equipment can be adapted to various heat sources such as steam, thermal oil, natural gas and flue gases.

Distinctive features:

PURPOSE:

Roll type veneer dryer where the drying agent is natural gas. Designed for drying veneer with a thickness of 0.8 to 8 mm. Equipped with a roller conveyor in four floors (4 tiers).

APPLICATION AREA:

It is used in medium-sized woodworking enterprises producing peeled veneer, plywood, bent glued parts of furniture and toys.

Processing scheme:

Principle of operation:

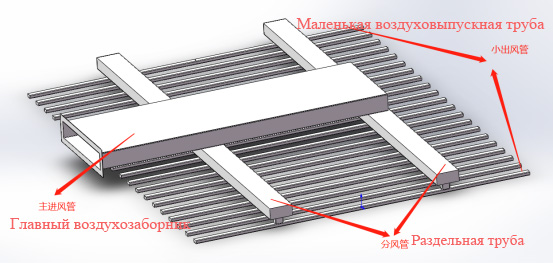

The veneer is placed on the loading side of the dryer and moved along a roller conveyor. Inside, streams of hot air from tubes with nozzle blast are directed onto its surface.

Additional equipment:

Automatic loader for dryer

Semi-automatic loader in the dryer

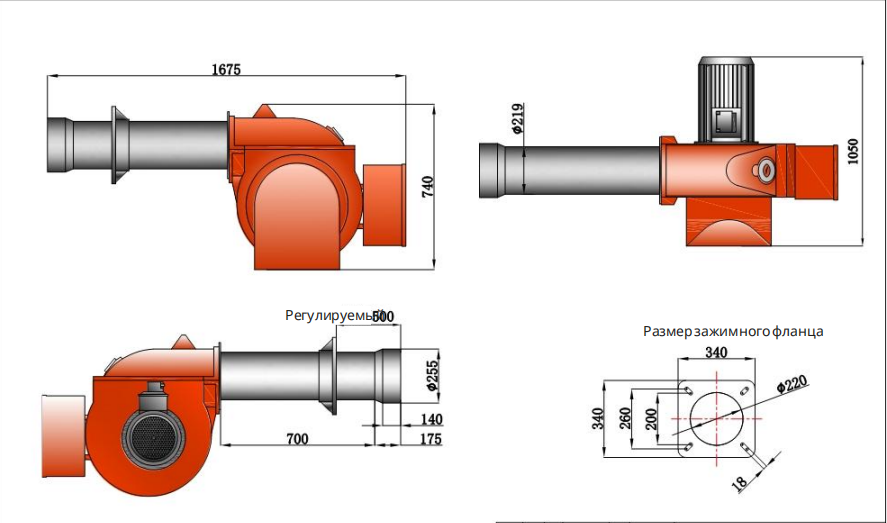

Natural Gas Burner(Gas Burner)

Project case:

Packing and transportation:

About company

Office building and production workshop.

Certificate

Customer visit