Veneer Drying System

Shine veneer drying With feeder has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect. The composite cost is only about $6-12/cubic meter, which can improve customers profit space greatly.

Plywood veneer dryer is a brand new generation wooden veneer drying system. By adopting modern global pressure touch veneer drying generation, Shine Roller veneer dryer has the benefit of excessive veneer drying capability, lowest function value, strength efficiency, and high-quality dried veneer. the veneer after drying has a uniform moisture content, is flat, has no waviness, and shrinkage is stored to a minimum. the floor is in proper condition for gluing for the plywood method. the new air fan and the cold air fan of the dryer use the contemporary axial flow fan, which reduces the strength intake and greatly reduces the electricity of the complete machine, which can further reduce the person's later operation price.

Product Advantages of Veneer Drying System

1. High-efficiency. It avoids the veneer stuck problems caused by unskilled manual loading , and cooperates with the dryer to dry the veneer more quickly.

2. Save labor costs. Machines can replace labor to the greatest extent. For example, in countries where labor costs are relatively high, fully automatic plate loading machines will be a better choice.

3. Increase production. The working upper limit of manual loading is fixed, but the fully automatic loading machine can set different speeds to match the drying speed of the dryer to maximize production capacity.

4. High degree of automation. The fully automatic plate loading machine is matched with the dryer to meet the high automation needs of customers with large output, improving the drying efficiency of veneers while ensuring drying quality.

Product Parameter of Veneer Drying System

Model No | GTH30-28 |

Working Width | 3.0m |

Deck | 4 |

Roller material | Q235B, φ102 special shaft tube |

Heating area length | 24m |

Cooling area length | 4m |

Veneer thickness and size | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 8-10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/day) | 80-85 |

Veneer transport speed | 5-22m/min,16A chain |

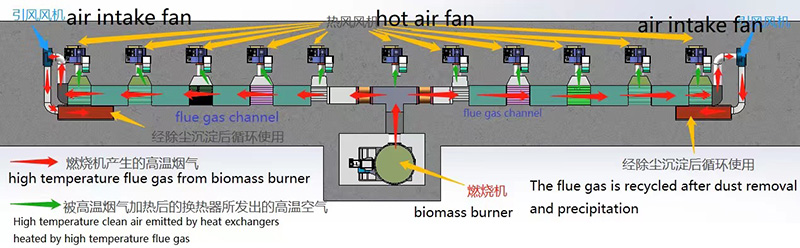

Hot air blower | Power: 4KW(24pc) |

Traction motor | Power: 5.5KW,frequency control(4pc) |

Cold air blower | Power: 4KW(4pc) |

Air intake fan | Power: 11KW(1pc) |

10 ton biomass burner | Power: 16.5KW |

Total power | 161.5KW |

Actual electricity consumption | About 114kwh per hour |

Overall Dimension(L*W*H) | 43m×12m×3.5m |

Customer Case

Certification

Factory

Packaging & Shipping