Biomass Dryer Machine

Biomass dryer machine can keep the veneer smooth after drying. Biomass drying machine equipped with water circulation system, which can save energy and improve efficiency. Biomass burner as heat for 40m 2 deck veneer drying machine, bark and other tree waste can be used as the fuels for veneer drying line, saving fuel cost significantly. The drying capacity of 40m 2 deck dryer can achieve 2.5m³ per hour. The composite cost of Shine biomass drying machine is only USD 6-12/per cubic meter.

Biomass Dryer Machine

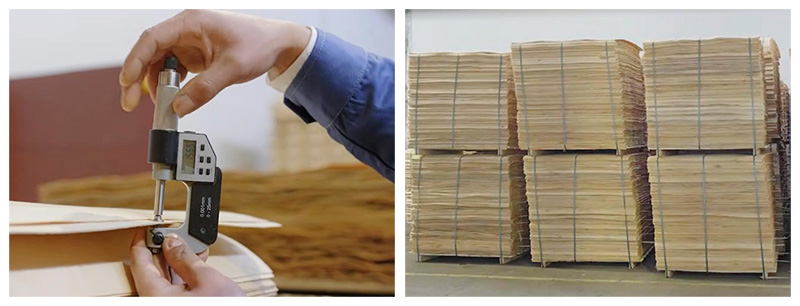

Direct heating air roller jet veneer dryer can eliminate heat loss in the veneer drying process. Among traditional timber dryer and heat sources, we have a very new biomass dryer machine that has the lowest veneer drying cost. The biomass burner eliminates the heat loss by directly heating air and supplying it to the dryer instead of indirect heating of oil or water. The lowest drying cost is as low as $12 per cbm. The moisture content is controlled by the drying temperature and veneer moving speed. Shine veneer drying machine is renowned for consistently producing high-quality veneer with uniform dry moisture content.

The biomass burner, a patented product independently developed by our company, can directly use crushed wood waste as fuel to provide a heat source for the dryer, no need to buy a steam boiler or thermal oil heater again. which is energy-saving and environmentally friendly, and greatly reduces the drying cost. The comprehensive drying cost for one cubic meter is about $10 lower than the thermal oil heater or steam boiler.

The temperature inside the burner is 40-60℃ higher than that of the traditional dryer (steam, thermal oil), and the temperature is controlled at 140-180℃, which shortens the drying time and increases the veneer drying output.

Product Parameter of Biomass Dryer Machine

Model No | GTH30-40 |

Working Width | 3m |

Deck | 2 |

Roller material | Q235B, φ89 steel pipe |

Heating area length | 36m |

Cooling area length | 4m |

Veneer thickness | 0.8-8mm |

Veneer water moisture | Fresh veneer to about 10% |

Heating material & drying temperature | Waste wood, 140-200°C adjustable. Temperature control accuracy ±5°C. There is automatic temperature control and speed regulation system, which can guarantee the moisture content is consistent. |

Drying capacity (m³/24h) | 55-65cbm |

Veneer transport speed | 5-22m/min,16A chain |

Hot air blower | Power:5.5KW(9pc) |

Traction motor | Power: 7.5KW,frequency control(2pc) |

Cold air blower | Power: 5.5KW(1pc) |

Air intake fan | Power : 11KW(2pc) |

4 ton biomass burner | Power: 16.5KW |

Total power | 109KW |

Actual electricity consumption | About 76kwh per hour |

Covered Space of the whole machine | 46M X 9M X 3M |

Exhibition and Customer Visiting

Certification

Factory

Packaging & Shipping